Your backhoe works hard for you every day. Return the favor with 30 minutes of maintenance, and it’ll run strong for years. Skip maintenance? You’re looking at breakdowns, lost jobs, and repair bills that’ll make your eyes water.

At FridayParts, we’ve seen the difference maintenance makes. Machines that get daily attention run 10+ years without major repairs. Neglected machines? They’re money pits by year five. These 10 maintenance tips come straight from operators to earn money for decades.

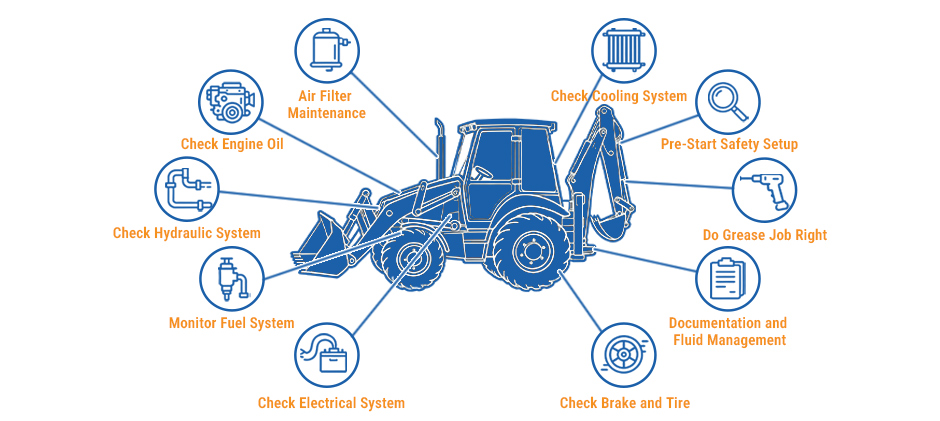

Tip #1: Master the Pre-Start Safety Setup

Before you even pop the hood of your equipment, safety comes first. This isn’t just about following rules – it’s about going home with all your fingers. Every maintenance session starts the same way: park on level ground, set the parking brake, and turn off the engine. Sounds basic? You’d be amazed at how many accidents happen from skipping these steps.

The most critical safety tool that most operators forget? The lift cylinder brace (LCB). This simple pin-and-brace setup prevents your loader arms from dropping while you’re working underneath. Here’s the right way: raise your loader arms, pull the pin securing the LCB, let the brace drop down to contact the lift cylinder rod. Push the pin through the lower holes and secure with a cotter pin. Now, slowly lower the loader until the brace takes the weight.

Never trust your hydraulics alone to hold loads. Even perfect cylinders can drift. That LCB is your life insurance policy. Use it every single time you’re under raised equipment. The five seconds it takes to install beats the alternative. We’ve heard too many horror stories about operators who thought they’d save time by skipping the brace. Don’t become another statistic.

Tip #2: Check Your Backhoe’s Engine Oil Like a Pro

Engine oil is your backhoe’s lifeblood, but checking it wrong gives false readings that can destroy your engine. Here’s how to get accurate readings every time.

First, timing matters. Check oil with the engine off but still warm – about 5-10 minutes after shutdown. This lets oil drain back to the pan while still flowing freely. Cold oil clings to engine parts, giving low readings. Hot oil hasn’t settled, giving high readings.

Pull the dipstick, wipe it completely clean, then reinsert it fully. Pull again for your reading. The oil level should sit between the “ADD” and “FULL” marks. Running low? Add oil slowly through the filler tube, checking frequently. Overfilling damages seals and creates foam that doesn’t lubricate properly.

What about oil color? New oil looks honey-golden. Normal, used oil turns darker brown. But if your oil looks black as coffee or has a milky appearance, you’ve got problems. Black means it’s way overdue for change. Milky means coolant contamination – stop running immediately and find the leak.

Tip #3: Hydraulic System Health Checks

Your backhoe’s hydraulic system moves mountains, but only when properly maintained. Daily backhoe hydraulic checks take two minutes but prevent thousand-dollar failures.

Start with the hydraulic oil level. Always check with the system depressurized – run all functions to the endpoints, then shut down and wait five minutes. Your sight gauge should show oil between the minimum and maximum marks. Low oil means either leaks or cylinder drift. Both need immediate attention.

But level isn’t everything. Oil condition matters huge. Clean hydraulic oil looks clear amber. Cloudy oil means water contamination. Dark oil indicates overheating or age. Metallic sparkles? Stop everything – metal particles mean component failure is happening right now inside your backhoe.

Temperature tells the truth. After an hour of work with your backhoe, your hydraulic tank should feel warm but not burning hot. If you can’t keep your hand on it, you’re overheating. Common causes include plugged oil coolers, relief valves stuck open, or internal leakage. Fix overheating fast – high temps destroy pump efficiency and cook seals throughout the system.

Tip #4: Air Filter Maintenance That Actually Works

Your engine breathes through its air filter. Clog it up, and you’re choking performance while washing cylinders with dirt. But here’s what most operators get wrong – you can overservice air filters, too.

Remove your filter housing and pull both primary and secondary elements. Hold the primary filter up to bright light. See light evenly through the pleats? It’s still good. Dark spots or no light penetration? Time for cleaning or replacement.

Cleaning technique matters. Never beat filters on tires or shop benches – you’ll damage the delicate filter media. Use compressed air at 30 PSI maximum, blowing from inside out. Work systematically around the filter, keeping the nozzle at least an inch away. See dust clouds? Keep going. No more dust? You’re done.

Secondary filters are different – never clean them. They’re your last defense against engine damage. Replace every third time you service the primary. Think of it as cheap insurance. A 30secondaryfilterpreventsa30 secondary filter prevents a 30secondaryfilterpreventsa10,000 engine rebuild.

Some backhoes have air filter service indicators – use them! When the indicator shows red, service immediately. Reset after service. These indicators measure actual restriction, not time, giving perfect service intervals for your specific conditions.

Tip #5: Smart Fuel System Monitoring

Water in diesel fuel is enemy number one. It causes injector failure, fuel pump damage, and microbe growth that clogs everything. Your fuel system needs daily attention, especially the water separator.

Locate your fuel filter and water separator bowl – usually transparent or translucent. Water sinks below diesel, appearing as a clear layer at the bottom. See any separation? Drain it immediately. Most separators have a drain valve at the bottom. Open it into a clear container until pure diesel flows out.

Pro trick: Check water separators every morning before starting. Condensation forms overnight, making water easier to spot. In humid climates or with temperature swings, you might drain water daily. That’s normal and way better than hydrolocking an engine.

Don’t forget your fuel cap and tank. Loose or damaged caps let moisture in. Check the seal – cracks mean replacement time. While there, peek in the tank with a flashlight. Rust, debris, or algae growth? You need professional tank cleaning before major damage occurs.

Tip #6: Cooling System Checks Save Engines of Your Backhoe

Overheating kills engines fast. Your cooling system prevents this disaster, but only when properly maintained. Daily checks prevent most cooling failures.

Check coolant level in the overflow reservoir – not the radiator cap unless stone cold. The level should sit between MIN and MAX marks. Low coolant means either external leaks or internal consumption. Find out which before major damage occurs.

But level alone doesn’t tell the whole story. Coolant condition matters too. Good coolant looks bright green, orange, or red (depending on type) and slightly transparent. Rusty brown means corrosion protection is gone. Oily film indicates head gasket or oil cooler leakage. Either demands immediate attention.

Don’t forget the radiator itself. Bent fins block airflow, causing overheating under load. Mud, bugs, and debris do the same. Use low-pressure water or compressed air to clean from the engine side outward. Straighten bent fins with a fin comb. A clean radiator runs 20-30 degrees cooler than a clogged one.

Tip #7: The 30-Point Grease Job Nobody Does Right

Here’s the maintenance most operators skip – and pay dearly for. Your backhoe has around 30 grease points between the loader, backhoe, and chassis. Miss even a few, and you’re buying expensive pins and bushings.

Start systematically. Work from one end to the other so you don’t miss points. Wipe each zerk fitting clean before attaching your grease gun. Dirty zerks push contamination into joints, accelerating wear. Pump until you see clean grease emerge from the joint – usually 3-5 pumps for pins, 5-10 for larger bushings.

Common missed points:

- Extendable stick sliding surfaces (clean old grease first!)

- Stabilizer float pins

- Bucket level indicator linkage

- Swing pin bushings

- Drive shaft U-joints

Don’t forget about door hinges and hood latches. They’re not just convenience items – seized hinges mean you can’t perform maintenance. A shot of grease every month keeps everything moving freely.

Quality matters with grease. Use proper specification grease for your climate. Cold weather needs different grease than blazing heat. Wrong grease either won’t pump or won’t stay put. Either way, your pins suffer.

Tip #8: Electrical System Vigilance of Your Backhoe

Electrical problems stop you cold. Unlike mechanical issues you might limp along with, dead batteries or fried wiring mean you’re done for the day. Stay ahead with simple checks.

Start with your battery. Check terminals for corrosion – that white/green fuzz that kills connections. Clean with a baking soda solution and a wire brush. Coat with dielectric grease to prevent return. Check battery hold-downs too. Loose batteries bounce around, breaking internal connections.

Inspect visible wiring for damage. Look for:

- Chafed insulation from rubbing

- Melted spots from overheating

- Rodent chewing (seriously common!)

- Corroded connections

Master switch discipline: Most backhoes have a battery master switch. Use it! Switch off at day’s end to prevent parasitic drain. Batteries last twice as long when not constantly trickling power to computers and clocks. Just remember to switch on before trying to start – we’ve seen too many “dead” machines that just had the master off.

Tip #9: Brake and Tire Safety Essentials of Your Backhoe

Brakes and tires don’t seem like daily maintenance items until they fail. Then they become emergency repairs that could’ve been prevented.

Your backhoe’s sealed brake system needs dealer service for major work, but you can monitor brake health. Check brake fluid level in the reservoir – low fluid means either leaks or worn pads. Look for wet spots around wheels, indicating leaking wheel cylinders. Test brakes before each day’s work. Both brakes should engage evenly without pulling.

Tire pressure matters more than most realize. Low pressure causes instability, especially with loads raised. Overinflation reduces traction and risks blowouts. Check pressure cold – tires heat up fast when working. Remember, pressure requirements change with axle loads. Loaded for roading needs a different pressure than a digging configuration.

Daily tire inspection catches problems early:

- Sidewall cracks from age/weather

- Tread cuts from job site debris

- Uneven wear indicates alignment issues

- Valve stem damage or leaks

Keep a tire pressure gauge in your toolbox. The 30 seconds to check beats waiting hours for mobile tire service.

Tip #10: Documentation and Fluid Management

The most overlooked maintenance tip? Writing it down. A simple logbook tracking maintenance pays huge dividends. Note oil changes, filter replacements, repairs, and unusual observations. This history helps diagnose problems and proves maintenance for resale value.

Fluid management isn’t just checking levels – it’s handling fluids responsibly. Every drop of oil, coolant, or hydraulic fluid is both expensive and environmentally hazardous. Use drip pans under work areas. Clean spills immediately with appropriate absorbents. Never let fluids reach storm drains.

Smart fluid practices:

- Label waste containers clearly

- Store new fluids properly to prevent contamination

- Recycle used fluids at appropriate facilities

- Keep spill cleanup supplies on your machine

- Fix leaks immediately – they never improve alone

That battery master switch we mentioned? Make it your end-of-day ritual. Switch off, log the day’s hours and any issues noticed, and plan tomorrow’s maintenance needs. This simple routine keeps you ahead of problems instead of chasing breakdowns.

Building Your Backhoe Maintenance Routine

Daily maintenance seems overwhelming until it becomes a habit. Start with this simple routine:

Every Morning (10 minutes):

- Walk-around inspection for leaks/damage

- Check engine oil

- Check hydraulic oil

- Check coolant level

- Drain fuel water separator

- Test brakes

Weekly (30 minutes):

- Grease all zerks

- Check the air filter indicator

- Clean the radiator if needed

- Check tire pressures

- Inspect battery/electrical

Monthly:

- Service air filters

- Check all fluid levels thoroughly

- Inspect pins and bushings for wear

- Test all safety systems

The key? Consistency beats perfection. Ten minutes daily beats two hours monthly. Small problems caught early stay small. Ignored problems become expensive adventures in breakdown repair.

Conclusion

Reading about maintenance doesn’t help – doing it does. Start tomorrow with these three steps:

- Create a maintenance log – Even a simple notebook works

- Stock basic supplies – Oil, filters, grease, and cleanup materials

- Set a routine – Same time daily prevents forgetting

Your backhoe doesn’t ask for much. Clean oil, fresh filters, proper grease, and daily attention keep it happy. In return, it’ll work reliably for years, earning its keep every day. Visit FridayParts to buy reliable backhoe parts now!