An engine oil pressure sensor (also called an engine oil sensor) is a simple part, but when it fails, it can trigger scary warning lights and alerts on the dashboard. If you notice one or more signs of a bad oil pressure sensor, it’s something you should deal with right away.

The Role of the Oil Pressure Sensor

The oil pressure sensor acts as the primary health monitor for the engine’s internal galleries. Its function is to measure the lubrication system’s internal pressure to ensure that rapidly moving metal parts—such as the crankshaft, cam lobes, and turbocharger bearings—remain separated by a thin film of oil. Under the high heat and friction of heavy-duty operation, maintaining this hydraulic wedge is the only thing preventing total seizure.

Top 4 Signs of a Bad Oil Pressure Sensor

Identifying a failing sensor early can prevent unnecessary panic and help prioritize heavy equipment maintenance. Look for these four primary symptoms:

Erratic or “Bouncing” Gauge Readings

A healthy oil pressure system typically shows steady, predictable readings that change gradually with engine RPM and oil temperature. If you notice the needle jumping back and forth rapidly—oscillating between 20 and 80 psi in a split second—it is a classic sign of an internal short. Real physical oil pressure rarely fluctuates with such violent speed; the “bouncing” is usually caused by a failing internal transducer diaphragm or a loose ground connection that is being interrupted by engine vibration.

Gauge Stuck at Zero or Absolute High

When a sensor fails completely, it often pushes the gauge all the way to one extreme. A short in the internal circuit sends a maximum voltage signal, keeping the needle at the highest reading even when the engine is idling. On the other hand, a broken signal wire, corroded plug, or damaged internal diaphragm will make the gauge read zero. Although a zero reading looks very alarming, it usually means a faulty sensor rather than a failed pump — as long as the engine runs smoothly and the oil level is correct.

Blinking or Spasmodic Oil Warning Light

In cases involving an oil pressure switch, the light should either be on or off. If the light flickers intermittently or blinks rapidly without a clear pattern, the sensor is likely failing. This “spasmodic” behavior is often triggered by the switch’s internal spring becoming weak or the electrical connector losing its grip on the pins. Furthermore, if you see the light flickering only when the machine vibrates during heavy digging or traveling, the fault is almost certainly electrical.

Visible Oil Leaks and the “Wicking” Effect

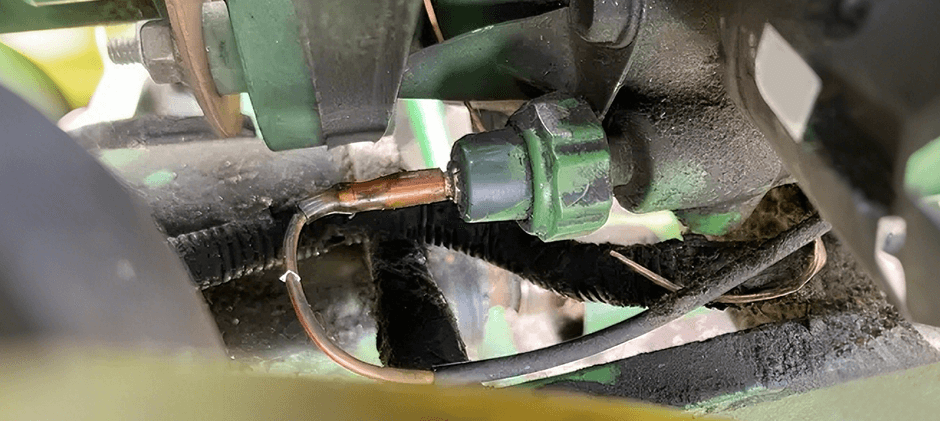

One of the most overlooked signs of bad oil pressure sensor health is a leak at the sensor body itself. These sensors often fail at the seam where the plastic electrical connector meets the metal housing. You may see oil dripping from the threads or, more dangerously, oil “wicking” into the electrical connector. In high-pressure environments, oil can be forced through the sensor body and into the wiring harness. If left unchecked, this oil can travel up the harness and eventually saturate the ECM, leading to electrical faults across the entire machine.

How to Tell if it’s the Sensor or a Mechanical Failure?

Distinguishing between a failed sensor and a mechanical disaster, you must evaluate the physics of the engine’s lubrication system. If the gauge reads zero but the engine sounds quiet and smooth, the sensor is likely the culprit. However, if you hear a ‘ticking top end’ or any grinding and clunking from the valvetrain, you are experiencing valvetrain starvation. Shut it down immediately to avoid a total loss.

Real Low Pressure

True low oil pressure symptoms are rarely just about the gauge. If the oil pump’s internal gears are worn or the pressure relief valve is stuck open in the “sump,” the pressure drop will be accompanied by physical symptoms. You will often observe an overheated engine, as oil is responsible for a significant portion of internal cooling. You may also smell burning oil or see “foaming” on the dipstick—a condition often caused by overfilling the oil, which allows the crankshaft to whip air into the lubricant, destroying its ability to hold pressure.

The Role of Oil Viscosity

Temperature and viscosity play massive roles in heavy equipment. If you are running 15W-40 oil in sub-zero temperatures, the oil may be too thick to reach the sensor quickly upon startup, triggering a temporary light. Conversely, if the engine is overheating, the oil can become too thin to maintain pressure at idle. On the other hand, if the machine is operating in a normal temperature range with the correct oil weight and the light remains on despite a smooth-sounding engine, the sensor is the prime suspect.

Why Oil Pressure Sensor Fails?

Off-road equipment operates in environments that are brutal on sensitive electronics.

- High-Frequency Vibration: Constant vibration leads to “fretting” of the electrical pins and fatigue of the internal sensor diaphragm.

- Environmental Debris: In forestry or demolition environments, sensors are often struck by debris. Or the wiring is snagged by a brush, leading to internal shorts.

- The Filter Screen Issue: Many engine designs feature a tiny filter screen located in the oil gallery directly under the sensor. Over time, sludge or carbon deposits can clog this screen, preventing the sensor from “seeing” the actual pressure in the block.

Technical Field Hack: If you think the sensor is working fine but the reading is still low, remove the sensor and check the screen inside. We recommend using a tapered tap. Gently thread it into the plastic frame of the screen just enough to grip it. Then pull it straight out for cleaning or replacement.

Diagnostic Steps: Testing the Oil Pressure Sensor

Before ordering parts, a field technician should follow these specific diagnostic steps to verify the fault.

- The Key-On, Engine-Off (KOEO) Test: Check the gauge before you even crank the engine. If the dash shows a reading—for example, 70 psi with the engine off—the sensor is internally shorted or the ECM is receiving a corrupted reference voltage. A healthy sensor should read zero when the engine isn’t turning.

- The Unplug Test: Unplug the sensor from the wiring harness. If the gauge was stuck high and now drops to zero (or vice versa), the wiring harness and the gauge cluster are functional, confirming that the sensor itself is the point of failure.

- Mechanical Pressure Verification: The only way to be 100% certain is to perform a mechanical test. Remove the sensor and install a manual oil pressure test kit into the port. Compare the manual gauge reading to the manufacturer’s specifications at both idle and full throttle. If the manual gauge shows 50 psi but the dash shows 10 psi, the sensor is faulty.

Get Reliable Sensors

If you notice any of these signs, it’s important to check whether the problem is the oil pressure sensor itself. You can inspect the sensor on your own, and if it needs to be replaced, FridayParts offers parts designed for high-vibration off-road environments. With a wide inventory, our sensors are compatible with major brands like John Deere, Caterpillar, Komatsu, and more.