For any owner of tracked heavy equipment, the undercarriage represents one of the single largest investments and ongoing costs. It can account for up to 50% of a machine’s total maintenance budget. While wear is inevitable, the rate of wear is not. By adopting a few simple, consistent habits, you can dramatically extend the life of your components, save thousands of dollars in repairs and fuel, and maximize your machine’s uptime. This guide provides 8 essential, field-tested tips to get the most out of your undercarriage, starting with the most important one.

Tip 1: Make Daily Cleaning a Non-Negotiable Routine

This is the single most effective thing you can do to extend the life of your undercarriage. The mixture of dirt, sand, and rocks that gets packed into your components is an incredibly abrasive slurry. Ignoring it is like pouring sand into a gearbox.

-

Why It’s Critical:

- Reduces Abrasive Wear: As the tracks turn, this gritty paste grinds away at your rollers, idlers, and sprockets like sandpaper.

- Prevents Freezing: In cold climates, wet mud can freeze solid overnight, seizing components. When an operator tries to move the machine, the immense force can cause severe damage to rollers and bearings.

- Saves Fuel: An undercarriage packed with mud can add thousands of pounds of dead weight, forcing the engine to burn more fuel just to move.

-

The Daily Process:

- Scrape First: At the end of each day, use a square-headed shovel and a long-handled scraper to knock off all the large chunks of mud and debris. This “dry cleaning” removes the bulk of the material and makes washing much faster.

- Pressure Wash Second: Use a pressure washer (ideally 3,000+ PSI) to clean the remaining grime.

- Focus on Components: Pay special attention to cleaning between each track roller, around the sprockets, and clearing all material from the large front idler and its tensioning mechanism. Proper undercarriage cleaning is the foundation of all other maintenance.

Tip 2: Conduct Rigorous Daily Inspections

A clean undercarriage is an inspectable undercarriage. You cannot see what you cannot inspect. This 5-minute walk-around after cleaning is where you catch small problems before they become catastrophic, job-stopping failures.

-

What to Look For:

- Leaks: Check the seals on the final drive motor and at the ends of each roller and idler for any signs of oil. A leak indicates a failed seal, which will lead to rapid bearing failure.

- Loose or Missing Hardware: Check for loose track pad bolts or bolts on the chain guard. A loose bolt can quickly lead to damage to the track chain itself.

- Abnormal Wear: Look for flat spots on rollers or teeth on the sprocket that are worn to a sharp point.

- Cracks: Inspect the track frame for any cracks in the welds, especially around mounting points for rollers and idlers.

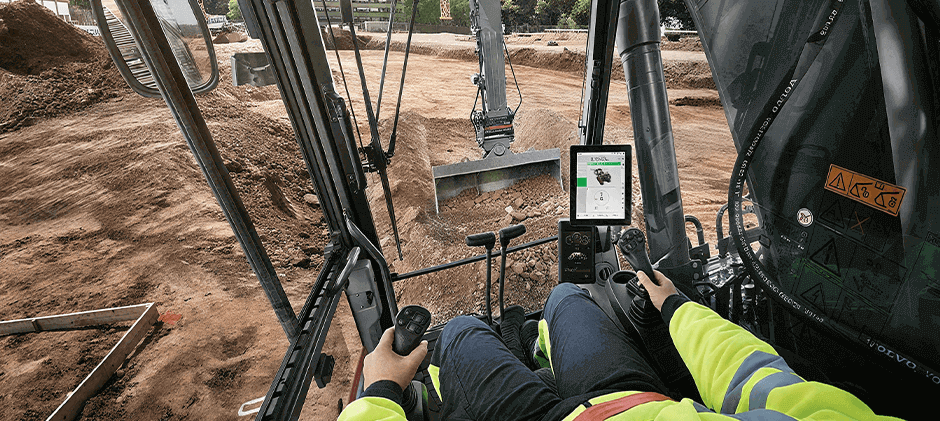

Tip 3: Master Smart Operating Habits

How you operate the machine has a direct impact on undercarriage life. Aggressive operation can cut the life of your components in half.

- Make Wide Turns: Avoid sharp, pivoting turns whenever possible. Counter-rotating or locking one track to turn puts immense side-load stress on all undercarriage components. Plan your movements to make wider, more gradual turns.

- Minimize Time on Slopes: Constant operation on a side-slope will cause accelerated wear on the downhill side of the undercarriage. When traveling up or down a hill for any distance, always position the final drive motors at the rear of the machine for better control and reduced wear.

- Reduce Unnecessary Spinning: Track spinning does not increase productivity; it only accelerates wear. Train operators to use smooth controls and let the machine’s weight and traction do the work.

Tip 4: Maintain Proper Track Tension

Track tension is a “Goldilocks” situation: it can’t be too tight or too loose. Incorrect tension is a primary cause of premature wear.

- Too Tight: A track that is too tight dramatically increases the load on pins, bushings, sprockets, and idlers. It wastes fuel and can lead to rapid failure.

- Too Loose: A track that is too loose can cause the track to “derail” or come off the rollers. It also causes instability and a slapping motion that puts impact stress on components.

As a general rule, check your operator’s manual, but a sag of 1.5-2 inches is typical. It’s also important to adjust tension for conditions: run tracks are slightly looser in muddy, packing conditions, and slightly tighter in hard or rocky terrain.

Tip 5: Choose the Right Track Shoe for the Job

Not all track shoes (or pads) are created equal. Using the wrong shoe width for your typical application can cause problems.

- Wide Shoes: These are best for soft conditions (like mud or sand) where you need maximum flotation to keep the machine from sinking. However, using wide shoes on hard, rocky ground makes them more prone to bending or cracking.

- Narrow Shoes: These are ideal for hard soil and rocky conditions. They offer better ground penetration and grip. Using them in soft conditions will cause the machine to sink.

The rule of thumb is to use the narrowest shoe possible that still provides adequate flotation for your job site.

Tip 6: Limit High-Speed and Reverse Travel

Most undercarriages are designed for the majority of wear to occur when traveling forward.

- Reverse Travel: The track pins and bushings are designed to rotate against each other under load, primarily in the forward direction. Extensive travel in reverse accelerates wear on the “wrong” side of the pin and bushing, effectively shortening their life.

- High-Speed Travel: While convenient, using the high-speed travel function for long distances dramatically increases the speed at which components wear. It multiplies the friction and heat in the system. Use high-speed travel sparingly.

Tip 7: Use Roller Guards Wisely

Full-length roller guards seem like a great idea for protection, but they can sometimes do more harm than good. While they are excellent at protecting rollers from high-impact damage (like in demolition or large rock quarries), in muddy or sandy conditions, they can be detrimental. They can trap abrasive material against the rollers and each carrier roller, preventing it from falling out and creating a “grinding box” that accelerates wear. Evaluate your application and use it only when impact protection is truly necessary.

Tip 8: Dig Over the Front Idlers, Not the Sprockets

This is a classic operator technique that has a huge impact on the life of your final drives.

- Digging Over Idlers (Correct): When you position the machine so you are digging over the front idlers, the force is transferred through the track chain to the idlers and into the track frame. The frame is designed to handle this stress.

- Digging Over Sprockets (Incorrect): When you dig over the rear sprockets, the force is transferred directly to the sprocket teeth, the final drive gearbox, and the drive motor. This puts immense strain on the most expensive parts of your drivetrain.

How To Prevent Undercarriage Problems?

Preventing problems is a summary of the tips above. If you see an issue, here is how to connect it back to a solution.

| Common Problem | Root Cause | Preventative Solution (Tip #) |

|---|---|---|

| Rapid Component Wear | Abrasive material is packed in components. | Daily undercarriage cleaning to remove debris. (Tip 1) |

| Seized or Failed Rollers | Contaminated bearings from damaged seals. | Regular inspections to spot leaks early. (Tip 2) |

| Uneven Wear on One Side | Consistently turning in one direction or working on side-slopes. | Alternate turning directions and balance machine orientation. (Tip 3) |

| De-tracking or High Fuel Use | Incorrect track tension. | Check and adjust track sag regularly for the conditions. (Tip 4) |

By following these tips, you can ensure that all your undercarriage parts, from the main track chain to each roller, last as long as possible, saving you significant money on repairs and downtime.

Maintain Your Undercarriage Now!

To engage in proactive preservation is, indeed, the sagacious manner for the governance of the undercarriage system’s expenditure. By the incorporation of these eight stratagems (most particularly the quotidian cleansing, the periodical inspection, and the standardized manipulation) into the diurnal labors, one may conspicuously abate the velocity of attrition. The perseverance unremitting shall safeguard thine investment, protract to the utmost the span of the components’ existence, diminish the protracted operational disbursement, and in the ultimate reckoning, assure the efficacious functioning of thy ponderous machinery.