When your off-road machinery suddenly stalls, struggles to start, or loses power under heavy load, a faulty camshaft position sensor may be the culprit. It can quietly disrupt the equipment’s precise timing, fuel injection, and ignition, leading to costly downtime. This article will explain how to recognize warning signs, test the sensor, and maintain optimal engine reliability.

What is the Camshaft Position Sensor?

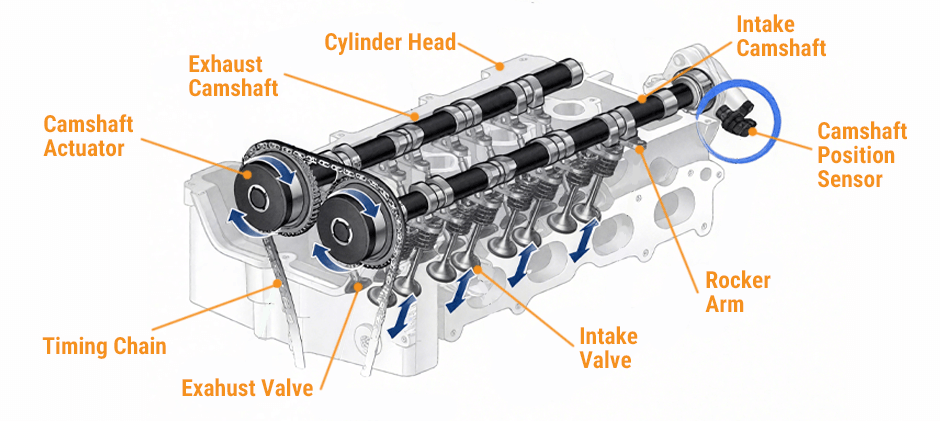

The camshaft position sensor constitutes an indispensable component within the realm of positional detection, entrusted with the observation of the camshaft’s rotational disposition and velocity in relation to the crankshaft. These real-time data are transmitted to the Engine Control Module (ECM), whereby the synchronization of fuel injection and ignition timing is orchestrated to attain the most felicitous combustion. Within off-highway diesel engines, such synchronization ensures a steadfast idle, prompt torque responsiveness, and an efficacious starting cycle even under the most inclement conditions.

Where Is the Camshaft Position Sensor?

While the exact location may vary by engine model, most off-road machinery places the sensor near the top or front of the engine — often adjacent to the timing cover or cylinder head. It sits close to a camshaft gear or trigger wheel, so it can detect minute variations in camshaft rotation.

A faulty sensor, damaged wiring, or magnetic interference can completely distort these signals, leaving the ECM guessing where each valve and piston should be — effectively crippling performance.

6 Signs of Camshaft Position Sensor Symptoms

Diagnosing a bad sensor early prevents misfires, wasted fuel, and unexpected shutdowns. Here are the most common indicators observed in off-road machinery:

1. Check Engine Light or Service Code Display

A lit check engine or fault indicator is the first visible clue. Connecting an OBD-II or J1939-compatible reader often reveals P0340–P0349 codes, which directly indicate issues within the sensor’s circuit or signal range. Ignoring these can lead to escalating sensor and ECU synchronization errors.

2. Hard Starting or No Start

Without accurate camshaft position data, the ECM fails to identify which cylinder is at the compression stroke. The result: long cranking or a complete failure to start, especially noticeable in cold or high-vibration conditions.

3. Irregular Idle and Engine Stalling

Engines that idle roughly or stall under light throttle frequently suffer from poor signal strength from a degraded position sensor. This causes mistimed ignition events and incomplete combustion — common in older loaders, excavators, and graders with high operating hours.

4. Reduced Power and Poor Torque Response

You’ll feel reduced pulling power when the ECM switches into a fail-safe “limp mode.” It restricts RPM to prevent internal damage, but that mode also cripples power output — a critical issue during soil compaction or hauling on slopes.

5. Excessive Fuel Consumption

Incorrect timing can keep injectors open longer than necessary. The result is wasted diesel, carbon buildup, and possible exhaust smoke. For fleets watching operating costs, this symptom alone justifies checking the camshaft position sensor before suspecting injectors or pumps.

6. Frequent Shaking or Vibrations

Abnormal vibration at idle or during deceleration might indicate signal dropouts from a dirty or magnetic-interference-compromised sensor. Cleaning or replacing this component often restores smooth power delivery.

Common Camshaft Position Sensor Fault Codes (P0340–P0349)

These standardized codes appear on both light-duty and heavy off-road equipment using electronic diesel control systems.

| Code | Meaning | Likely Cause |

|---|---|---|

| P0340 | Circuit Malfunction | Broken wire, connector corrosion |

| P0341 | Range/Performance Error | Out-of-sync camshaft signal |

| P0342 | Circuit Low | Low reference voltage |

| P0343 | Circuit High | Open circuit or excessive voltage |

| P0344 | Intermittent Signal | Vibrations or EMI (electromagnetic interference) |

| P0345–P0349 | Bank B Sensor Issues | Dual-cam configurations |

In some machines, these codes may appear in proprietary CID/FMI formats. Regardless of display style, they all indicate improper sensor feedback that disrupts timing commands and injector control.

How to Check if the Camshaft Position Sensor is Bad?

Testing isn’t complicated — it’s about measuring voltage, continuity, and waveform accuracy.

- Locate the Sensor: Kindly consult the service manual to ascertain its exact position and to discern the power wire, the grounding wire, and the signal conductor with appropriate caution.

- Check Power Supply: Employ the digital multimeter in the direct current voltage mode to verify that the sensor is indeed endowed with the proper electrical potential (commonly 5 volts).

- Test the Signal: When the engine commences its operation, observe meticulously the sensor’s output. Under ordinary circumstances, the sensor shall emit an alternating voltage in the form of a square wave. Should the waveform appear absent, flattened, or fluctuating without stability, it may be deduced that the sensor has succumbed to malfunction.

- Inspect Physically: Detach the sensor with prudence; scrutinize for the presence of metallic fragments, fissures, or oily contamination—all of which may interfere with the magnetic extremity of the device.

If you discover heavy wear or inconsistent voltage during testing, it’s time to replace it. Here’s where quality matters: mid-range aftermarket options often fail under vibration and heat. Consider reputable suppliers offering high-durability aftermarket sensor replacements designed for extended duty cycles in off-road conditions.

How to Reset the Camshaft Position Sensor?

Resetting often doesn’t involve pressing a button; it involves clearing the adaptive values from the engine control module:

- Replace or Reinstall the Sensor Securely.

- Disconnect the battery for 10–15 minutes to clear stored voltage memory.

- Reconnect and reinitialize by switching the ignition ON without starting for a few seconds.

- Perform a short idle cycle — allow the ECM to relearn synchronization with the new signal pattern.

Alternatively, proprietary diagnostic software (such as Caterpillar ET or Cummins Insite) can perform an adaptive reset instantly through the “Cam/Crank Sync Relearn” process. If your diagnostic confirms the issue, replacing your sensor with a reliable unit is straightforward.

At FridayParts, you can find durable replacements through our electrical parts section — designed to match OEM specifications at a fraction of the cost. Because the camshaft position sensor belongs to your engine’s electrical parts group, proper material protection and heat shielding are vital.

Summary

Ignoring the warning signs of a faulty camshaft position sensor may cause even the most powerful off-road engine to stop unexpectedly. Regular checking, early finding of problems, and timely changing of parts keep the machine running with good fuel use and strong performance. FridayParts provides a wide collection of excellent aftermarket sensors, wire harnesses, and other related parts for many kinds of equipment brands. Buy now to lessen machine resting time with trustworthy components at fair prices. The next engine rebuilding begins with accuracy — and we are here to assist you in reaching it.