Coolant keeps the engine at the correct operating temperature all the time. But how does the cooling system know if the engine is hot now? The answer is—coolant temperature sensor. This small sensor sends temperature data to the ECM, and the system can keep track of the engine’s operating status. Read on, we’ll talk about the coolant temperature sensor location, common failure symptoms, and how to replace it, step by step.

What Is the Coolant Temperature Sensor?

Basically, the engine coolant temperature sensor is just a tiny part that senses temperature. When the temperature changes, its electrical resistance changes right along with it. The ECM—think of it as the engine’s brain—sends a steady voltage to the sensor. Then it tells if the engine is cold or hot by reading how that voltage changes.

This isn’t just for showing a temperature number on your dashboard. The ECM depends a lot on this signal to adjust the engine’s performance in real time. That’s how it keeps your heavy-duty diesel engine fuel-efficient and safe. It will specifically affect these aspects:

- Fuel injection timing and injection volume: Cold and hot engines require different oil supply methods. ECM optimizes fuel supply based on coolant temperature data, making cold starts smoother and the engine more fuel-efficient once it reaches operating temperature.

- Preheating plug work: When it is cold, the ECM will refer to the coolant temperature to determine the heating time of the glow plug to ensure that the engine can start smoothly.

- Hydraulic fan control: Many excavators and loaders use hydraulically driven cooling fans. ECM adjusts fan speed based on temperature data —making the fan run faster with heavy loads and slower with light loads, saving power and fuel.

- Engine protection measures: If the sensor detects that the temperature is too high, the ECM will trigger the fault light alarm, reduce the engine power to avoid damage, and even stop the engine directly in serious cases.

Overall, coolant temperature sensors are an important data source for the ECM. Its accuracy directly affects the fuel consumption and emissions of the machine, as well as the long-term service life of the engine.

Coolant Temperature Sensor Location

Where do you find this sensor? On most machines like excavators and tractors, the coolant temperature sensor is usually in the same kinds of spots. It’s almost always screwed right into a coolant passage. Check these three main places:

- Near the thermostat housing: The thermostat controls coolant flow, so this is a great spot to get an accurate engine temp reading. Look for a small sensor with a 2 or 3-wire electrical connector. It’ll be on or right next to the housing where the big radiator hose hooks up to the engine.

- In the cylinder head: Some engines have the sensor threaded straight into the cylinder head. It sits in the coolant passages that run around the combustion chambers, so it gets a direct read of the engine block’s temperature.

- On a coolant pipe or manifold: Less often, the sensor might be on a coolant manifold or the main pipe that runs from the engine to the radiator.

- One more thing: some bigger engines have two separate sensors. One sends data to the ECM for engine control. The other, simpler one (usually a single-wire sender) runs the temperature gauge on your dashboard.

If your gauge shows normal temps but you’re seeing signs of a bad sensor, the problem’s probably with the one that talks to the ECM. Always check your machine’s service manual for the exact sensor location—this way you won’t mix things up.

How to Spot a Faulty Coolant Temperature Sensor?

When an ECT sensor fails, it sends wrong data to the ECM—or no data at all. This wrong info makes the ECM mess up, and you’ll notice some issues. A quick visual check is a simple way: look for a cracked connector, rusty pins, or coolant leaking from the sensor itself. But most problems are inside the sensor; you can’t see them. Here are the most common signs your ECT sensor is failing:

- Worse fuel economy: If the sensor gets stuck reading “cold,” the ECM will keep pumping extra fuel, thinking the engine’s still warming up. This rich fuel mix wastes diesel and hits your wallet hard.

- Black smoke from the exhaust: That extra fuel doesn’t all burn up in the engine. It burns in the hot exhaust system instead, making thick black smoke—especially when the machine’s under load.

- Engine overheating: A sensor that doesn’t report rising temps is dangerous. The ECM won’t know to kick the radiator fan into high gear, so the engine overheats. This can cause serious damage, like a warped cylinder head or seized parts.

- Hard starting (especially when it’s cold): If the sensor lies to the ECM and says the engine’s already warm, the glow plugs won’t work right. That makes it tough to start the engine on cool days, or it’ll start rough.

- Rough idle: A bad fuel mix makes the engine idle all wonky—surging or stumbling as the ECM tries and fails to find a steady running state.

- Check engine light or other warning lights: On modern machines, the dash warning light will almost always pop on when the ECM detects a problem with the ECT sensor circuit. It’ll also trigger if it gets a totally illogical signal—like the engine showing it’s at operating temp just one second after a cold start.

Common Trouble Codes Related to a Bad ECT Sensor

When it comes to the engine coolant temperature sensor, the trouble code will be linked to SPN 110. The FMI code tells you exactly what’s wrong:

- SPN 110, FMI 3: Voltage too high, or open circuit. The sensor’s unplugged, a wire’s broken, or the sensor’s failed internally (causing an open circuit). The ECM will read max voltage.

- SPN 110, FMI 4: Voltage too low, or short circuit. This points to a short between the signal wire and ground, or an internal short in the sensor itself. The ECM will read nearly zero voltage.

- SPN 110, FMI 0: Data valid but above normal operating range. The sensor’s working fine—but it’s actually reporting a real overheat issue. This is a critical code. You need to shut down the engine right away and check the cooling system.

- SPN 110, FMI 2: Data erratic, intermittent, or wrong. The signal is unstable or doesn’t make sense—it might jump around randomly. Common causes are loose connections, internal sensor failure, or corroded wiring.

If you see any of these codes, the problem is almost definitely with the ECT sensor or its wiring harness.

How to Replace a Coolant Temperature Sensor?

Replacing an ECT sensor is an easy job—most machine owners can do it with basic tools.

Tools You’ll Need

- Deep socket set and ratchet

- Wrench set

- Clean the drain pan

- Shop rags

- Thread sealant (if the new sensor doesn’t already have it on)

- Replacement coolant (if needed)

Replace It Step by Step

Safety First

Park the machine on flat ground and make sure the engine is completely cool. A hot cooling system is under pressure and can burn you bad. Disconnect the negative battery cable, and do any lock-out/tag-out steps your machine requires.

Put a Little Coolant

Place a clean oil tray under the radiator drain valve, open the drain valve, drain some coolant, and keep the liquid level below the sensor position. In this way, it is not easy to leak everywhere when removing the sensor. If the coolant is still clean and relatively new, you can save it for further use.

Locate and Unplug the Sensor

Locate the ECT sensor in the location you said before. Press and hold the clip on the plug and pull it straight out without pulling on the wiring harness.

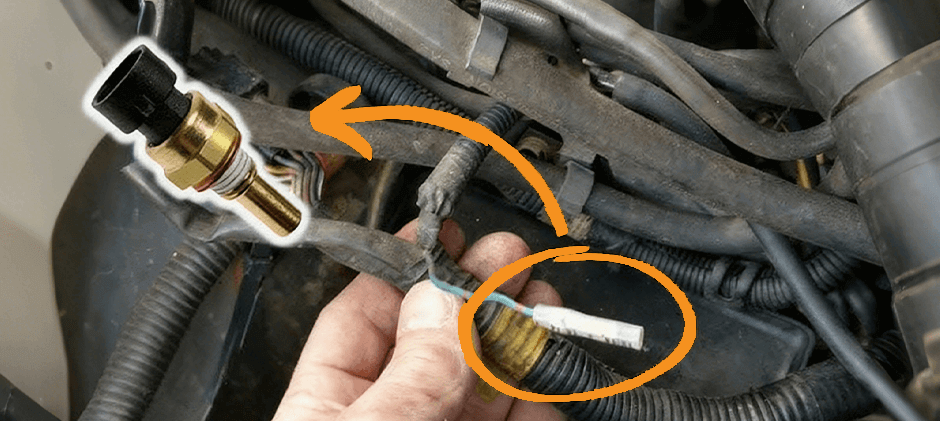

Remove the Old Sensor

Use a deep socket or wrench of the appropriate size to loosen the sensor counterclockwise. When it is loose, it can usually be unscrewed by hand.

Install a New Sensor

Wipe the thread position on the engine clean. See if there is sealant on the threads of the new coolant temperature sensor, if not, just apply a little. First screw the new sensor in by hand to make sure it is not twisted crooked, then tighten it slightly with a wrench. Don’t use too much force. Generally, just tighten it by hand and then tighten it a quarter turn.

Plug it Back in and Add Coolant Back In

Plug the plug back into the new sensor and hear “click” the instruction is stuck. Close the drain valve and slowly add back the coolant that was previously released, or the new coolant.

Drain the Air and Check the Effect

The cooling system easily gets air in, and the air should be drained cleanly according to the repair manual. Connect the battery back, start the engine, see if there is any leakage around the new sensor, observe the water temperature gauge, and confirm that the heating process is normal and the reading is stable. Finally, clear the fault code with diagnostic equipment.

Summary

If the engine temperature reading is still erratic after the repair, you might need to consult a professional technician. The problem could be a wiring fault, a bad thermostat, a blown head gasket, or even an ECU (Engine Control Unit) malfunction. These issues all need a full diagnosis before any repair work is done. If you need to replace the ECT sensor, FridayParts has them in stock and ready to ship. We guarantee low prices, so you can get your machine back up and running without going over your repair budget.