If you have just replaced the oil seal of your engine but still find oil leakage after several days or even weeks, in ninety percent of the cases, the matter mostly lies with the shaft or the pressure situation. Merely changing a damaged oil seal without understanding the fundamental reason behind the failure will often result in the same trouble recurring. In this writing, we shall explore deeply the genuine causes that bring about the new oil seal’s failure, so that you may settle the issue rightly from the very beginning and let your machine work dependably.

What are the Causes of Engine Oil Leakage?

Before we focus on recurring leaks, it’s helpful to understand the common sources of an oil leak on heavy machinery like excavators, loaders, and tractors. The severe working surroundings, ceaseless trembling, and the burden of immense loads impose extraordinary strain upon the engine’s internal organs.

-

Degraded Gaskets

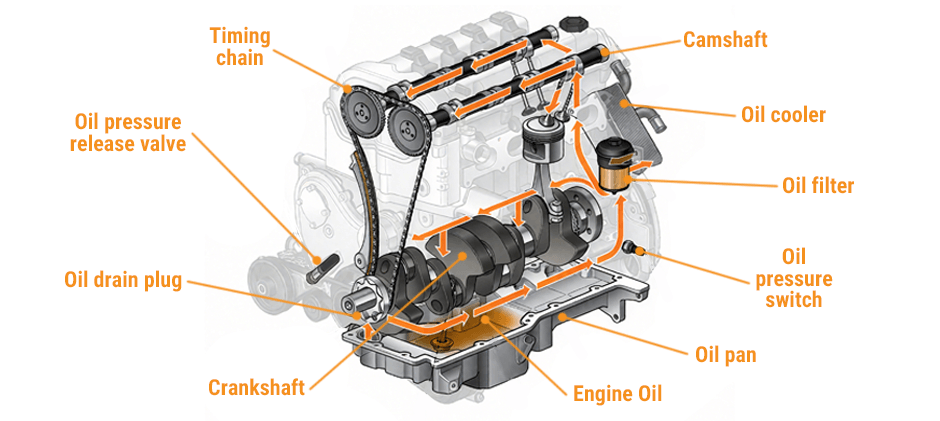

Gaskets are flat seals interposed between two motionless engine portions, as between the valve cover and cylinder head, or the oil pan and engine block. As countless hours pass, the cruel heat and oppressive pressure render these gaskets hardened, brittle, and fractured, whereby oil doth seep through the fissures.

-

Damaged Oil Pan

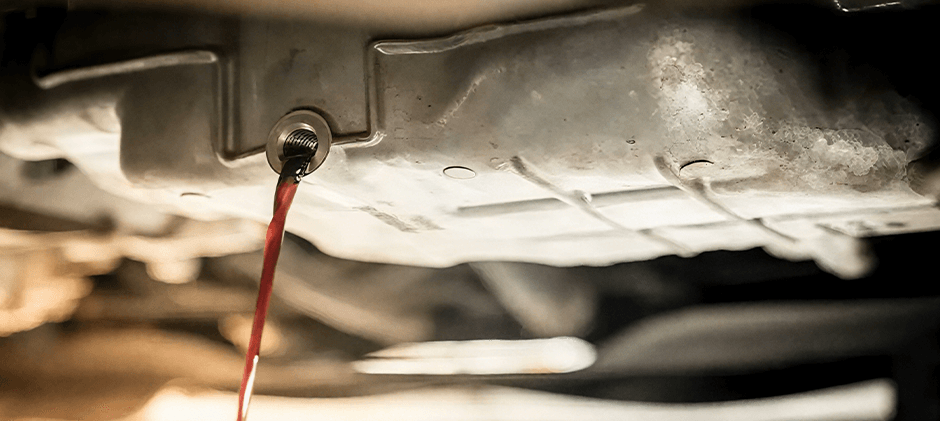

The oil pan, being the vessel that holds the engine’s lifeblood at its base, is most exposed to the perils of the worksite — rocks, stumps, and other misfortunes of the ground. A dent may warp its sealing surface, whilst a crack will occasion grievous leaking. Even the humble drain plug may betray the engine, should it be tightened too much, too little, or fitted with a washer past its prime.

-

Failed Oil Seals

These form the very heart of our present discourse. An oil seal is used where a rotating shaft passes through a stationary housing, such as the crankshaft exiting the engine block (front and rear main seals) or the camshaft. Its solemn duty is twofold: to keep the oil within and to bar the filth without.

-

Loose Fittings or Damaged Lines

Engines upon heavy machines are adorned with many outward conduits — for the oil cooler, the turbocharger, and other such workings. Yet, through constant quivering, the fittings may grow loose, and hoses, once supple, may turn brittle or rupture, thereby granting oil a path to escape.

Though any of these maladies may give rise to leakage, the most confounding misfortune occurs when a brand-new oil seal begins to weep again soon after its fitting — a sure omen that a graver ailment lies beneath.

Why Do Oil Seals Repeatedly Leak Oil?

This is the key question. If you’ve replaced the seal and yet another leak develops in the same place, the cause usually lies beyond the seal itself. Persistent oil seal leaks are often due to mechanical imbalance, improper installation, or material degradation.

1. Aging and Heat Fatigue

Rubber materials lose elasticity when exposed to constant temperature cycles. In diesel-powered loaders, tractors, or excavators, operating heat can easily exceed 120°C around the crankshaft area. Once the rubber hardens, it loses its sealing flexibility.

High-grade seals made from fluorine or silicone rubber offer a longer lifespan under such conditions. Always opt for quality materials when working with high-temperature engines.

2. Shaft Misalignment and Surface Damage

A bent or worn shaft surface is one of the most overlooked causes of recurring oil seal leaks. Off-road machinery often operates in high-vibration conditions; bearings and shafts can gradually develop radial runout.

When the shaft is no longer perfectly centered, the seal lip cannot maintain full contact, allowing oil to escape. A worn shaft may also have grooves cut into it after long-term friction—something no new seal can fully compensate for without repair.

| Mechanical Issue | Impact on Seal Performance | Repair Recommendation |

|---|---|---|

| Shaft misalignment | Uneven wear on the seal lip | Realign or replace the shaft |

| Shaft scoring/grooving | Oil bypasses the worn track | Install sleeve or polish shaft |

| Bearing looseness | Vibrations tear the sealing edge | Replace bearings before the seal |

3. Improper Installation Techniques

Incorrect installation is a frequent issue. Striking or leveraging an oil seal with a screwdriver can deform its edge, while failing to apply grease during mounting can cause dry friction during first start-up, shortening the seal’s lifespan immediately.

Using a proper seal driver ensures the component goes in evenly and seats flush with the housing bore. Always check that the lip spring remains intact and the sealing surface is lubricated.

4. Contaminants or Blocked Venting

Dust, mud, and internal pressure can destroy seals fast. Off-road engines that operate in dirty or wet environments often allow fine particles to collect around the housing. These particles grind against the sealing surface, cutting micro-grooves that become oil escape routes.

Additionally, when crankcase vents or transmission vents clog, pressure builds and pushes oil out through even the tightest seals.

How to Fix That Oil Leak?

A consistent oil leak must be addressed systematically rather than reactively. Follow these steps:

1. Clean and Identify the Source

Degrease the engine and observe. Start from the top (valve cover, sensors) and move downward (timing cover, crankshaft area). Tracing fresh oil trails helps pinpoint the real cause.

2. Check for Pressure Buildup

Inspect breather hoses or PCV systems. If air cannot vent properly, even perfect seals will push out oil under operating pressure.

3. Examine the Shaft and Bearings

Replace or repair scored shafts. Use sleeves where possible or regrind lightly if within tolerance.

4. Install Correctly with Proper Tools

Lubricate the seal lip with oil or assembly grease. Use seal drivers to press-fit the component evenly, avoiding any deformation of the edge or retaining spring.

5. Check Seal Orientation and Material Specification

Make sure the lip faces inward toward the oil flow. Confirm that the material (NBR, FKM, PTFE, etc.) matches the intended oil type and temperature environment.

6. Perform a Final Pressure and Leakage Test

Run the engine and recheck. A clean, dry surface after a few operating hours confirms that the issue is resolved.

Seal It Right, Run It Strong

Oil leakage after the replacement of the seal may indicate the existence of more profound mechanical or installation problems. Before one proceeds to install the new seal, it is most necessary to examine carefully the alignment of the shaft, the balance of pressure, and the purity of oil. For those off-road machines that are laboring under severe and heavy loads, investing in seals of superior aftermarket quality is essential to guarantee the lasting stability of the system. FridayParts is offering durable and economical aftermarket oil seal solutions, which are particularly made for the harsh applications of tough machinery, thus ensuring that your engines shall remain clean, efficient, and without leakage. Kindly visit FridayParts.com to acquire replacement parts that will cause your equipment to perform with reliability throughout the year.