If you’re learning how to use an excavator, are curious about its parts, or simply need to understand its structure to better maintain your equipment, then this article is perfect for you. FridayParts breaks down an excavator into its core components and explains their functions to help you better understand your excavator. This article will give you a clear understanding of the structure of an excavator, tailored for both beginners and seasoned operators.

Main Excavator Components At a Glance

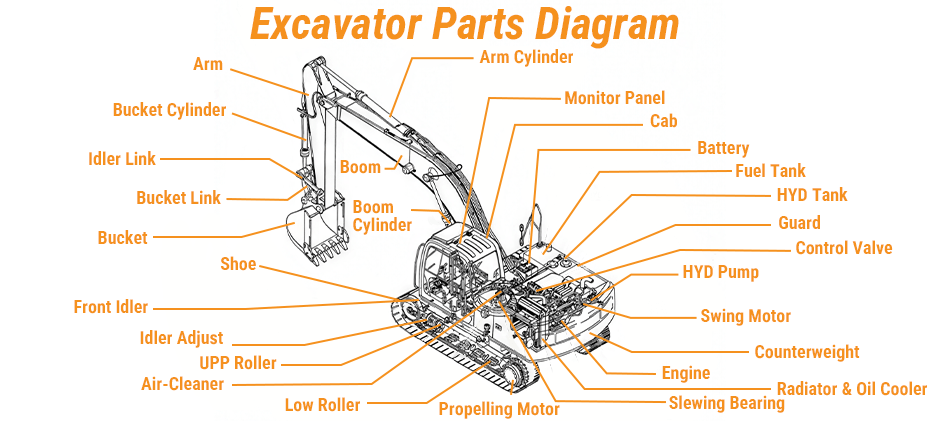

An excavator can be broken down into three main sections: the house (or superstructure), the undercarriage, and the arm (or boom). Each section contains a group of components with a specific purpose.

| Component Group | Key Parts | Primary Function |

|---|---|---|

| The House | Cab, Engine, Hydraulic Pump, Fuel/Hydraulic Tanks, Counterweight, Swing Motor. | The operational hub and power center of the machine. It houses the operator and the main power-generating components. |

| The Undercarriage | Tracks, Rollers, Idlers, Propelling Motor, Slewing Bearing. | The mobile foundation of the excavator. It provides stability and allows the machine to travel across the job site. |

| The Arm | Boom, Arm (Stick), Bucket, Hydraulic Cylinders, Linkages. | Boom, Arm (Stick), Bucket, Hydraulic Cylinders, Linkages The “business end” of the excavator. This is the assembly that performs the digging, lifting, and moving of materials. |

Key Parts of Excavator and Their Functions

The House (Superstructure)

The house sits on top of the undercarriage and rotates 360 degrees. It contains the operator’s cab and the primary power systems.

1. Operating Systems

- Cab: This is the excavator’s command center. The operator sits here, not bothered by harsh weather and job-site hazards. Modern cab design emphasizes comfort and safety, usually equipped with ROPS (Rollover Protective Structure).

- Monitor Panel: Located inside the cab, the digital display serves as the machine’s nervous system. It shows engine temperature, fuel level, hydraulic pressure, and operating hours, etc. When problems are detected, it will also display error codes.

2. Power Systems

- Engine: Excavator’s power source. usually use a high-torque diesel engine, for the whole machine to provide power, drive the hydraulic pump, and the electrical system.

- Radiator & Oil Cooler: Working alongside the engine, these components are critical for temperature regulation. The radiator cools the engine coolant, while the oil cooler performs the same function for the hydraulic fluid, preventing overheating during heavy use.

- Battery & Air-Cleaner: The battery provides the electrical power to start the engine and run the electronics. The air cleaner is vital for protecting the engine by filtering out dust and debris from the air before it enters the combustion chamber. A clogged air filter can significantly reduce engine power and efficiency.

3. Hydraulic Systems

- HYD Pump (Hydraulic Pump): If we say the engine is the power source, then the hydraulic pump is the heart of the machine. It obtains mechanical energy from the engine and converts it into hydraulic energy, thereby driving the boom cylinder, bucket cylinder, swing motor, and propulsion motor. The wear of the hydraulic pump is a common cause for a performance slow-down or weakening.

- Control Valve: This is the brain of the hydraulic system. When the operator moves the joysticks in the cab, the control valve directs the flow of high-pressure hydraulic fluid to the correct components, such as the boom or bucket cylinders, allowing for precise movements.

- Fuel Tank & HYD Tank: These tanks store the essential fluids for the machine. The fuel tank holds the diesel, while the hydraulic tank holds the hydraulic oil. Keeping the fluid in both tanks clean is crucial for the machine’s health.

4. Swing & Stability

- Swing Motor : This hydraulic motor is in charge of driving the entire house on the undercarriage to rotate. It cooperates with the swing bearing to provide a 360-degree rotation that is smooth and controllable.

- Counterweight: A heavy cast iron block installed at the rear of the house. Its sole function is to offset the weight of the loads in the boom and bucket, providing the necessary stability to prevent the excavator from tipping over during excavation and lifting operations.

The Undercarriage

The undercarriage is the firm foundation for supporting the entire machine and enabling its movement. Its parts are constantly subject to wear and tear.

- Slewing Bearing (Swing Bearing): This large gear ring is the key connecting point between the machine’s house and its chassis system. It allows the house to smoothly rotate and must bear great forces.

- Propel Motors (Travel Motors): Normally, there are two such motors, with one for each track. These hydraulic motors transform hydraulic pressure into turning force to drive the tracks and make the excavator move forward or backward.

- Rollers (Low Roller & UPP Roller): These are wheels that guide the track chain along the track frame. The lower rollers bear the machine’s weight, while the upper rollers support the track’s return path. These are high-wear items that require regular inspection.

- Front Idler & Idler Adjust (Track Adjuster): The front idler is a large wheel at the front of the track frame that guides the track. The idler adjust is a hydraulic or grease-filled cylinder that pushes against the idler to maintain proper track tension.

- Shoe (Track Pad): These are the individual steel plates that make up the track chain. They are what make direct contact with the ground, providing traction. Track shoes wear down over time, especially when working on abrasive surfaces like rock or concrete.

The Arm and Attachment

This is the assembly that performs the work, controlled by a series of powerful hydraulic cylinders.

- Boom: The largest section of the arm is connected directly to the house. Its primary function is to provide the main vertical reach for the digging assembly.

- Boom Cylinder: These are the large hydraulic cylinders (usually two) that connect the house to the boom. They are responsible for raising and lowering the boom.

- Arm (Dipper or Stick): This section connects the boom to the bucket. It provides the “in and out” motion, allowing the operator to pull material towards the machine or extend the bucket for greater reach.

- Arm Cylinder: This huge single-cylinder is used for propelling the boom to forward and backward moving.

- Bucket: Excavator’s work-end. bucket has many shapes and sizes, suitable for from general digging to trenching and leveling, and so forth various task.

- Bucket Cylinder: That cylinder controls the bucket’s curling and extending motion, enabling it to scoop, lift, and tip materials. Because the bucket keeps moving and is exposed externally, its sealing parts are easily worn.

- Bucket Link & Idler Link: These are part of the linkage assembly (often called the “dog bone” and “H-link”) that connects the bucket cylinder and the arm to the bucket itself. This geometry allows the bucket to articulate through its full range of motion.

When these core excavator components wear out, finding reliable excavator parts is essential to minimize downtime and keep your projects on schedule.

Common Uses of Excavator Components

Although “digging” is the main use, each part can cooperate to accomplish many tasks:

- Trenching: Requires precise control of the boom and the bucket to dig a foundation that is narrow and deep.

- Grading: Utilize the flat edge of the bucket and the controllable boom movement to level and smooth the terrain.

- Material Handling: Boom, dipper, and bucket are used for lifting and loading trucks carrying dirt, rocks, or debris.

- Demolition: By the help of a hydraulic hammer or grapple attachment, using the power of the hydraulic system to crush concrete or deal with waste material.

- Traversing rugged terrain: The robust design of the undercarriage enables the machine to cope with uneven ground, mud, and slopes at the construction site.

Troubleshooting Common Excavator Component Issues

| Symptom | Possible Cause(s) | Potential Solution |

|---|---|---|

| Slow or Weak Hydraulics | Low hydraulic fluid; Clogged hydraulic filter; Worn hydraulic pump. | Check fluid level; Replace filter; Inspect pump for wear or damage. |

| Machine Drifts or Won’t Stay Still | Worn seals in a hydraulic cylinder; Issue with the control valve. | Inspect cylinders for leaks; Have the control valve tested by a technician. |

| Excessive Track Noise | Worn rollers or idlers; Improper track tension (too loose or too tight). | Inspect undercarriage components for wear; Adjust track tension. |

| House Won’t Swing Smoothly | Low swing motor pressure; Damaged slewing bearing. | Check hydraulic pressure to the swing motor; Inspect slewing bearing for damage or lack of grease. |

In Summary

Every single part of the excavator cooperates together for your work bring great convenience. Understanding these components and their functions can help you operate the equipment more proficiently. Meanwhile, when your excavator parts become clear cognition, you will be able to check and repair the excavator with precise judgment of which accessory is wrong, convenient you timely and quickly replace the needed parts. Meanwhile, FridayParts, as an excellent representative of parts suppliers, always for your part replacement, guards the escort.