It is wise to invest in the Ingersoll Rand brand for an air compressor in the heavy equipment industry, its long-standing history and excellent quality make it an ideal choice for many professionals and investors.

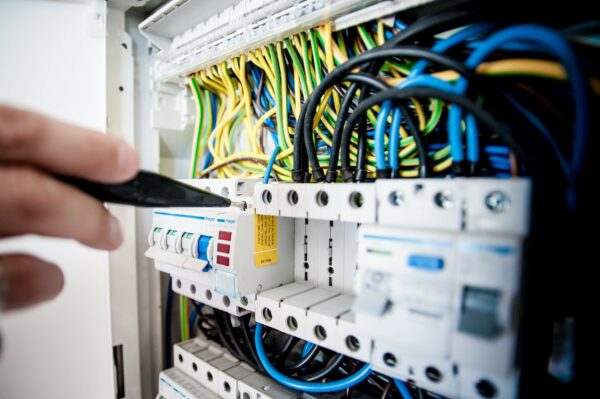

If you plan to wire by yourself, wiring an Ingersoll Rand air compressor can be challenging compared with upgrading Ingersoll Rand air compressor parts. Proper wiring ensures safe operation and effectiveness. Here is a simple guide to help you wire the Ingersoll Rand air compressor more efficiently.

What tools should I prepare for wiring?

Having the necessary tools ready before starting is good practice to avoid interruptions. Here are some tools that can assist you in completing the wiring and maintenance tasks for your Ingersoll Rand air compressor:

Wire Stripper: Right wire strippers based on the wire gauge can remove the insulation from cables or wires effectively.

Plier: It can help you secure, bend, or tighten wire connectors.

Cable Cutter: Cable cutters are designed specifically for cutting cables and typically have sharp cutting blades and sufficient cutting force to handle thicker cables.

Crimping Tool: It is used to create reliable electrical connections, ensuring that the wires are securely fastened within the connectors.

Insulated Terminal Crimping Tool: It helps install insulated sleeves, which protect the insulation at wire connections and provide additional protection.

Wire Marking Tool: It is used to label wires or cables for easy identification, tracking, and management of different wires.

Wire Cutter: It helps you quickly cut thinner wires.

Please use the right tools based on your wiring requirements to assist you in completing the wiring and maintenance tasks for your Ingersoll Rand air compressor.

How to wire an Ingersoll Rand air compressor?

- Ensure that the air compressor is in a shutdown state and disconnected from the power source.

- Select the appropriate power voltage and phase based on your region and power supply. Ensure that your power supply matches the power requirements of the air compressor.

- Ensure that all electrical components and wiring comply with electrical safety standards and local electrical regulations.

- Connect the air compressor to the power source using suitable cables and plugs. Follow the markings on the wiring panel or junction box of the Ingersoll Rand air compressor to correctly connect the phase, ground wire, and neutral wire.

- Use electrical insulation sleeves or insulation tape to protect wire ends and connections.

- Carefully inspect all connections to ensure there are no loose or exposed wires.

- If the air compressor is equipped with a control panel or controller, connect the control circuit according to the manufacturer’s instructions.

- After completing the wiring, carefully inspect all connections to ensure there are no errors. Ensure that all fasteners are properly installed.

- Before restarting the air compressor, double-check all electrical connections to ensure they comply with safety standards.

Important: The specific wiring steps may vary depending on the model and specifications. If you are unfamiliar with the wiring process, it is recommended to seek assistance from professionals with expertise in equipment maintenance to avoid safety hazards.

Incorrect wiring can lead to the following issues

- Malfunction or damage: Incorrect wiring may prevent the air compressor from functioning properly or cause it to malfunction. This can include issues such as the motor fails to start, unstable operation, or complete shutdown.

- Electrical problems: Wiring errors can result in electrical issues such as overloading, short circuits, or voltage instability. This can damage the electrical components of the air compressor and pose safety risks such as electric shock or fire hazards.

- Triggering of protective devices: Many air compressors are equipped with protective devices such as overload protectors and circuit breakers. If wiring errors cause the current to exceed safe limits, these protective devices may be triggered, causing the air compressor to shut down or the power to be cut off.

- Safety concerns: Incorrect wiring can lead to safety hazards. For example, improper grounding increases the risk of electric shock, while the absence of safety switches may prevent the timely disconnection of power in case of emergencies.

- Damage to other equipment: Wiring errors can also cause damage to other related equipment or systems. For instance, the incorrect connection of control wires can affect control logic or other devices.

The following ways can help find professionals if you are unsure.

- Contact the official support team of Ingersoll Rand air compressors.

- Reach out to the dealers or suppliers selling Ingersoll Rand air compressors.

- Consult with engineers or electrical experts.

Shall I rewire when replacing Ingersoll Rand air compressor parts?

It depends on which part of the Ingersoll Rand air compressor you need to replace. Typically, rewiring is done when replacing or repairing electrical components. If the issue involves electrical connections or circuits, rewiring may be necessary. However, if it only consists of the failure of specific parts or components, replacing the parts should suffice, and it is an easy task. If you plan to upgrade or replace parts, you can find cost-effective Ingersoll Rand aftermarket parts here, welcome to contact us.