For heavy equipment, quality lighting can’t be overlooked. It is crucial for both safety and productivity, serving as an extra pair of eyes for the operator in dark or poorly lit environments. Therefore, choosing the right LED light for heavy equipment is crucial for improving productivity, safety, and efficiency. This guide will provide you with some reference to select heavy equipment LED lights, such as brightness, beam pattern, and durability. You can see clear as day—whether you’re working early in the morning or late at night.

The Importance of LED Work Lights

Turning old halogen lights to modern LEDs is one of the most effective upgrades for your heavy equipment. Its benefits aren’t just about brightness.

- Enhanced Visibility and Safety: The biggest advantage is the quality of light. LEDs produce a crisp, clear white light that is much closer to natural daylight. This reduces eye strain for operators during long nights and dramatically improves depth perception. For an operator in a cab, this means being able to better spot hazards, identify uneven terrain, and navigate a crowded job site safely.

- Incredible Lifespan and Durability: Off-road environments are brutal. Constant vibration, shocks from rough terrain, and exposure to weather will destroy lesser lights. LEDs are solid-state devices with no fragile filaments, making them extremely resistant to shock and vibration. While a halogen bulb might last 500 hours, a quality LED work light is often rated for 30,000 to 50,000 hours. This means fewer replacements, less downtime, and more reliability.

- Energy Efficiency and Cost Savings: LEDs consume significantly less power than halogen or HID lights to produce the same amount of light. This reduces the electrical load on your machine’s alternator and battery. Over time, this lower power draw can even contribute to minor fuel savings. Because they last so long, you also save on the recurring cost of replacement bulbs and the labor to install them.

What to Consider When Choosing LED Work Lights

These LED lights are important for giving you good visibility and keeping you safe in tough or dim workplaces. There are some factors to consider to ensure you make the right choice.

Lumens (Brightness)

Lumens (lm) measure the total amount of light a bulb produces. It’s easy to think that more lumens are always better, but that’s not necessarily true. The goal is to have the right amount of light for the task, not just the most. Too much light in a small space can cause glare, which is just as dangerous as not enough light.

For general illumination around a machine like a skid steer or mini excavator, a light producing 2,000 to 4,000 lumens is often sufficient. For larger machines like full-size excavators or wheel loaders that need to light up a wide work area, you might look for lights in the 4,000 to 6,000 lumen range or use multiple fixtures.

Think of lumens as your total light output. For broad illumination around a machine, 3,000-5,000 lumens is a great start. For focused, long-distance tasks, you might need a spot beam with similar output but different optics to direct that light effectively.”

Beam Pattern

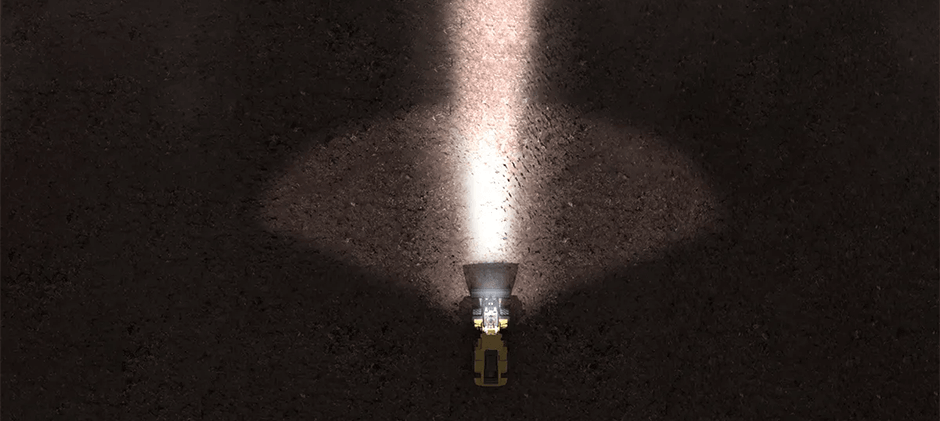

The beam pattern describes how the light is distributed. This is just as important as the brightness. Choosing the wrong pattern means your lumens are wasted by lighting up the wrong areas. The three main types are Flood, Spot, and Combo.

Flood Beam: This pattern creates a wide, even spread of light over a large area, but doesn’t reach very far. It’s perfect for illuminating the immediate work zone directly in front of or beside your machine. This is the most common pattern for general LED work lights.

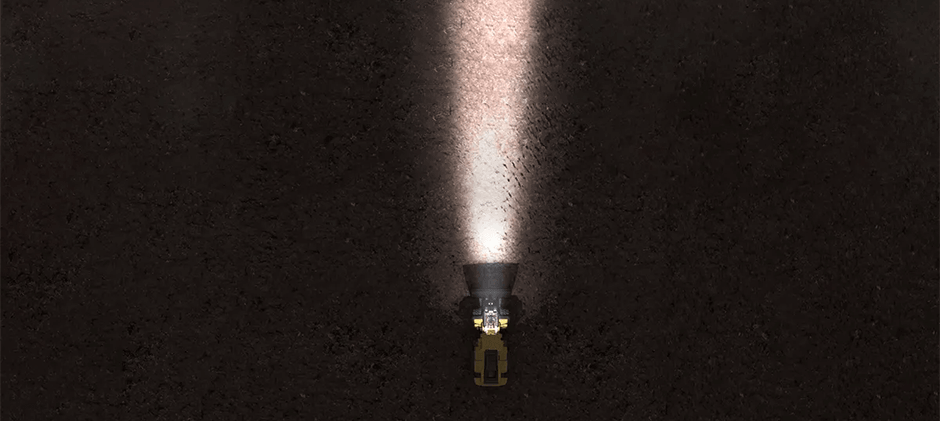

Spot Beam: This pattern concentrates the light into a narrow, focused beam that travels a long distance. It’s ideal for seeing far down a haul road, inspecting the top of a stockpile, or identifying obstacles in the distance.

Combo Beam: As the name suggests, this combines both flood and spot optics into a single light fixture. It gives you a good mix of wide, close-range illumination and long-distance visibility, making it a versatile choice.

Durability and Weather Resistance

Your heavy equipment LED lights will be exposed to rain, mud, dust, and constant shaking. Durability is non-negotiable.

IP Rating: Look at the IP Rating (Ingress Protection). This indicates the light’s resistance to dust and water. This two-digit number tells you how well the light is sealed against solids (first digit) and liquids (second digit). For off-road machinery, you should look for a rating of IP67 or higher. An IP67 rating means the light is completely dust-tight and can be submerged in up to 1 meter of water for 30 minutes. An IP68 rating offers even more robust water protection, typically for continuous submersion.

Construction Material: A housing made from die-cast aluminum is ideal because it’s strong and acts as a heat sink. Check that the mounting hardware is stainless steel to prevent rust and corrosion.

Vibration resistance: Ensure the luminaire is designed to withstand the vibrations and shocks common in agricultural operations.

Color Temperature (CCT)

Color Temperature, measured in Kelvin (K), describes the color of the light. A lower Kelvin value (~2700K-3500K) produces a “warm” or yellowish light, similar to a halogen bulb. A higher value (~5000K-6500K) produces a “cool” or bluish-white light that mimics natural daylight.

For heavy equipment operations, a cool white light between 5000K and 6500K is generally preferred. This color range enhances contrast and clarity, making it easier for operators to distinguish between different materials, spot hazards, and work with precision. In very dusty or foggy conditions, a slightly warmer light can sometimes cut through the particles better, but for most applications, daylight-like color is best.

Mounting Options

How will the light attach to your machine? Most heavy equipment LED work lights use a pedestal or stud mount, which offers flexibility in aiming the light. Before you buy, check the mounting locations on your excavator, dozer, or loader. The goal is to find a light with a bracket that fits your machine with minimal or no modification. A versatile mounting bracket that allows for easy tilting and swiveling is a huge plus, as it lets you direct the light exactly where you need it.

Certifications and Standards

Look for certifications like CE, RoHS, or SAE, which indicate that the light has been tested to meet specific safety, environmental, and performance standards. They show that the manufacturer has invested in proper testing and stands behind their light’s performance and safety.

Bottom Line

You know your job site needs best. Maybe you need to replace old halogen lights, add specific spotlights for long-distance work, or extra lights when the factory setup isn’t enough. At FridayParts, you don’t have to pay extra for OEM upgrades to do this. We have a wide inventory of high-quality LED work lights. Most major heavy equipment brands are compatible. Get the right lights at a lower price on our one-stop website. Easily light up your work area!