How long does it take to charge a battery? For an operator, few things are more frustrating than turning the key of your machine in the middle of a job site and hearing… nothing. A dead battery doesn’t just delay you—it stops the entire operation. A common question we hear: “If I run the machine hard enough, will that recharge the battery?”

The short answer: Not reliably. Your alternator can top up a healthy battery, but it’s not designed to recover one that’s been drained flat. Depending on conditions, driving or running the engine may only partly restore power—and can even damage your charging system. Here’s what you need to keep in mind.

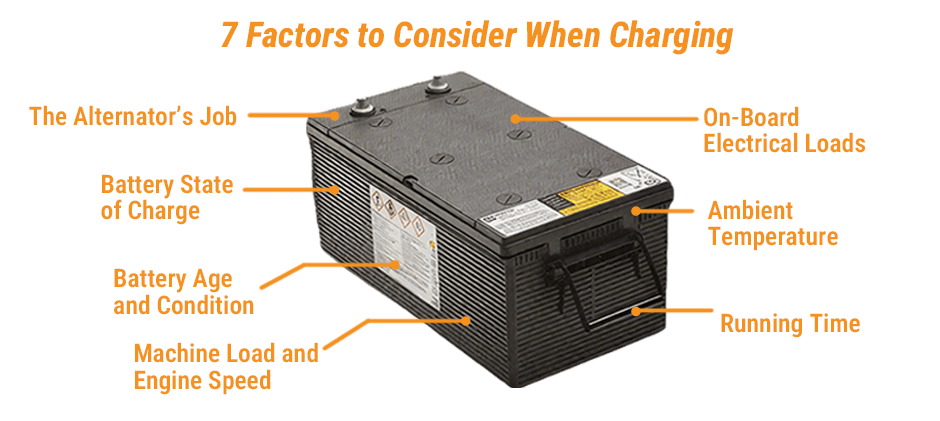

7 Factors to Consider of Charging a Battery

1. The Alternator’s Job

Your alternator is built to maintain charge while powering hydraulics, lights, A/C, and controls. It’s not a heavy‑duty charger. Forcing it to recover a flat battery can overheat the alternator and lead to costly downtime.

2. Battery State of Charge

- A healthy 12V battery: 12.6–12.8V.

- Around 12.2V: half full.

- 12.0V or below: flat.

- Below 11.8V for long = sulfation, which permanently reduces storage ability. Once sulfation sets in, running the machine for hours won’t bring the full capacity back.

3. Battery Age and Condition

- Newer batteries accept a charge quickly.

- Older ones have higher internal resistance and take charge slowly.

- Each deep discharge permanently weakens the battery. Equipment batteries that have gone flat multiple times are unreliable for heavy jobs.

4. Machine Load and Engine Speed

- Alternator output rises with engine RPM. Machines working at steady operating RPMs charge better.

- Extended idling hardly charges at all.

- Heavy work lighting, fans, or auxiliary tools also take power away from charging.

5. On‑Board Electrical Loads

- Running the cab lights, cameras, GPS, fans, and radios reduces the current available to the battery.

- Best practice: switch off all non‑essential loads if trying to restore charge during operation.

6. Ambient Temperature

- Cold makes the chemical reaction inside the battery sluggish—it takes longer to accept a charge.

- Heat above normal limits forces systems to reduce charging current to protect the battery from overheating.

- Extreme weather on job sites makes charging inconsistent.

7. Running Time

- Topping off after a normal start: 20–30 minutes of steady operation usually restores what was lost.

- Recovering after a jump‑start: several hours of uninterrupted running may get close to a full charge, but it overworks the alternator.

- Reviving a battery left flat for days: driving or running the engine won’t restore it—the damage is permanent.

Approximate Time for Different Scenarios

- Normal Top‑Up: Battery is healthy and only down from starting the machine → 20–30 minutes of normal operation covers it.

- After a Jump‑Start: Battery too weak to crank without help → 2–4 hours of steady running may restore some charge, but this stresses the alternator. Don’t rely on this repeatedly.

- Dead for Days: Battery voltage below 11.5V and sitting → sulfation likely. Running the machine won’t fix it. Forcing it risks alternator failure. Replace or properly recharge with an external unit.

The Smartest Approach to Solve the Battery Problem

- Use a dedicated charger in the shop or yard. A slow, proper charge restores batteries far better. For a step-by-step guide, see our post on how to charge a battery properly.

- Test the battery after charging. If it can’t hold power, replace it before it fails mid‑shift.

- Remember: the alternator should focus on keeping your machine running—not recharging a battery back from the dead.

Downtime costs more than a new battery. Protect your alternator, protect your schedule—equip yourself with the right battery charger and quality replacement battery accessories from a reliable source like FridayParts. Order today!