After identifying the rod bearing failure, it’s also important to know how to choose the right size of a rod bearing.This guide from FridayParts cuts straight to the point. We will show you exactly how to understand the confusing “undersize” measurements, correctly select the right bearing for your crankshaft, and verify the fit, ensuring you prevent expensive damage and get your machine back to making you money.

What is a Rod Bearing and Why Do Different Sizes Exist?

Before we can select a bearing, we must first understand its job. What is a rod bearing in an engine? It’s not a ball bearing with rolling elements. Instead, it’s a precision-engineered shell, a type of “plain bearing,” that sits between the connecting rod and the crankshaft journal.

Its primary function is to create a microscopic space, known as oil clearance. High-pressure engine oil is forced into this gap, creating a hydrodynamic wedge—a powerful film of oil. The crankshaft doesn’t actually touch the bearing; it floats on this oil film, allowing it to rotate thousands of times per minute with minimal friction.

This oil clearance is the engine’s lifeblood. It’s incredibly precise, typically measuring between 0.025mm and 0.075mm (0.001″ to 0.003″), about the thickness of a human hair.

The entire purpose of having different bearing sizes is to maintain this exact oil clearance under different engine conditions.

A. Standard (STD) Bearings

- Application: Used in brand-new engines from the factory or in engines where the crankshaft journals show no measurable wear and are still within the original equipment manufacturer’s (OEM) standard specifications.

- Bearing Characteristic: This is the thinnest, or “baseline,” thickness for a rod bearing. It’s designed to perfectly match a standard-sized crankshaft journal.

B. Undersize (US) Bearings

Here is the most critical concept to grasp, and it’s where most mistakes are made.

- Application: Over hundreds or thousands of hours of hard work, the crankshaft journals can wear down from friction, causing their diameter to become smaller. To repair this, a machine shop will grind the crankshaft journal down to a perfectly smooth and round, but smaller, diameter. This is a standard procedure in engine rebuilding.

- Bearing Characteristic: To compensate for the material removed from the crankshaft, a thicker bearing shell is needed to “fill the gap” and restore the original, precise oil clearance. This thicker bearing is called an “Undersize” (US) bearing.

Let’s clarify the confusing terminology:

“Undersize” refers to the crankshaft journal it fits, NOT the bearing itself.

- An undersized crankshaft journal is smaller than standard.

- An undersized bearing is thicker than standard.

This is the root cause of many engine rebuild failures. An inexperienced mechanic might see a worn, undersized journal and mistakenly order a thinner bearing, leading to massive oil clearance, zero oil pressure at the rod, and immediate, catastrophic rod bearing failure.

Common undersized grades for off-road machinery include:

- 0.25mm (or .010″): This is the first level of repair. The bearing wall is approximately 0.125mm thicker than standard to make up for the 0.25mm reduction in the crankshaft’s diameter.

- 0.50mm (or .020″): The second level of repair. The bearing wall is about 0.250mm thicker than standard.

- 0.75mm (or .030″): A common third level, and often the last recommended stage of grinding for many crankshafts.

Summary of the “Why”: The only physical difference between bearing sizes is their wall thickness. A thicker (undersized) bearing is used to maintain the life-saving oil clearance when paired with a crankshaft journal that has been machined to a smaller diameter.

A Step-by-Step Guide to Selecting the Right Rod Bearing

Choosing the correct connecting rod bearing is a process of precision measurement, not guesswork. Using the wrong size is a guarantee for failure, turning your rod bearing replacement project into a full engine replacement.

Step 1: Precisely Measure the Crankshaft Journal

You cannot select a bearing without knowing the exact diameter of the crankshaft journal it will be riding on.

- Disassemble & Clean: Remove the connecting rod cap and old bearing shells. Thoroughly clean the crankshaft journal with a solvent to remove all oil and debris.

- Use the Right Tool: You need an outside micrometer, not a simple caliper. It must be accurate to at least 0.001mm or 0.0001″.

- Measure Diligently: Measure the journal’s diameter in at least three different spots along its width (left, middle, right) and in at least two different orientations (e.g., 90 degrees apart). This process checks for “taper” (uneven wear along the width) and “out-of-round” conditions. Record the smallest measurement you find.

Step 2: Determine the Crankshaft’s Size Grade

1. Consult the Service Manual: Your machine’s official service manual is your single source of truth. It will list the original standard (STD) diameter for the crankshaft journals, along with acceptable wear limits and the specifications for each undersize grade.

2. Compare and Calculate:

- If your smallest measurement falls within the STD range specified in the manual, you will order STD bearings.

- If your measurement is approximately 0.25mm (.010″) smaller than the STD range, the crank has likely been machined before, or it needs to be machined to this size. You will need 0.25mm US bearings.

- Follow the same logic for 0.50mm, 0.75mm, and other undersized increments.

Crucial Pro Tip: If your measurements show the journal is worn beyond the standard limit but not yet at the next undersize level, or if it is out of round, you must send the crankshaft to a professional engine machine shop. They will grind it perfectly to the next clean-up size (e.g., 0.25mm US), and you will then order bearings to match. Do not try to “fix” a worn crank with a new bearing alone.

For Example:

Let’s imagine you are working on an engine, and your service manual provides the following specifications for the connecting rod journals:

- Standard (STD) Diameter: 54.000 mm – 54.020 mm

- First Undersize (0.25 US) Diameter: 53.750 mm – 53.770 mm

- Service Limit (Max Wear for STD): 53.980 mm

Now, you precisely measure your crankshaft journal and get the following readings:

A: Your smallest measurement is 54.015 mm.

- Analysis: This falls squarely within the STD range.

- Action: Order STD size bearings.

B: Your smallest measurement is 53.970 mm.

- Analysis: This is below the STD service limit (53.980 mm) but not down to the 0.25 US size. The journal is worn out of spec.

- Action: You must send the crankshaft to a machine shop. They will grind it down to the next clean-up size, which will be within the 53.750 mm – 53.770 mm range. You will then order 0.25mm US bearings to match the newly machined crank.

C: Your smallest measurement is 53.760 mm.

- Analysis: This falls perfectly within the 0.25 US range. This indicates the crankshaft has already been machined once before.

- Action: Order 0.25mm US size bearings.

Step 3: Verify Oil Clearance with Plastigage

Even after careful measurement and selection, you must perform a final verification. This step is non-negotiable and is what separates professional engine builders from amateurs.

1. Use Plastigage: This is a very thin, deformable plastic thread.

2. Procedure:

- Place a small piece of Plastigage across the clean crankshaft journal.

- Install the new rod bearing shells into the connecting rod and cap.

- Install the connecting rod and cap over the Plastigage and torque the bolts to the exact specification listed in your service manual. Do not rotate the crankshaft.

- Carefully remove the rod cap. The Plastigage will be crushed flat.

3. Measure the Clearance: The Plastigage packaging includes a paper gauge. Compare the width of the crushed strip to the gauge to read the exact oil clearance.

4. Confirm: Ensure this measured clearance falls within the acceptable range specified in your service manual. If it’s too loose or too tight, you must stop and re-diagnose the issue before proceeding.

Understanding this can also help you replace the rod bearing.

The Invisible Difference in Engine Bearings

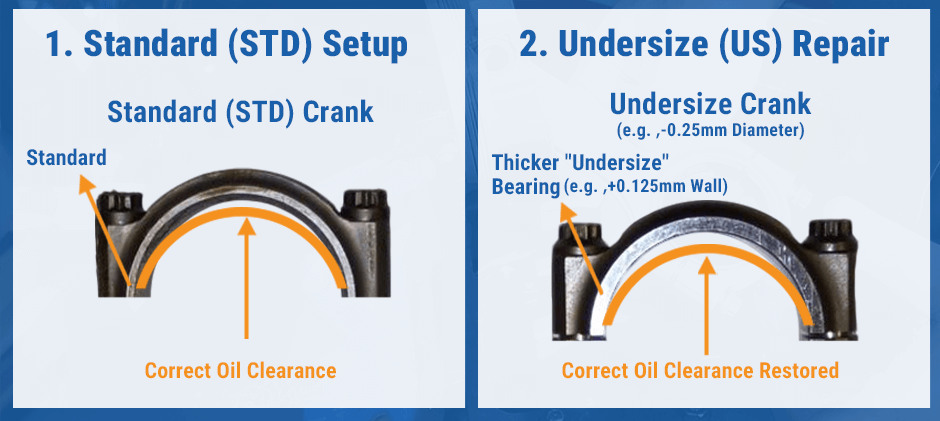

The thickness difference between an STD and a 0.25mm US bearing shell is only about 0.125mm—barely visible to the naked eye. That’s why you can’t rely on visual comparison. The diagram below explains the concept:

- Standard (STD) State: A new, standard-sized crank journal pairs with a standard bearing to create the perfect oil clearance.

- Worn State: The crank journal wears down. If you use another standard bearing, the gap becomes too large. This causes oil pressure to drop, leading to metal-on-metal contact, heat, and the infamous “rod knock.” This is one of the primary causes of rod bearing failure.

- Repaired (Undersize) State: The worn crank is machined to a smaller, uniform undersize dimension. A thicker undersized bearing is installed, which perfectly compensates for the smaller journal, restoring the correct oil clearance and ensuring a long, reliable service life.

Connecting Rod Bearing Size Chart

This table summarizes the relationship between the marking on the bearing, its thickness, and the crankshaft it’s designed for.

| Bearing Marking | Common Name | Bearing Wall Thickness | Fits Crankshaft Journal Size | Application |

|---|---|---|---|---|

| STD | Standard | Baseline Thickness (Thinnest) | Standard (STD) Diameter | New or non-worn crankshafts within OEM specifications. |

| 0.25mm / .010″ | First Undersize | Thicker than STD by ~0.125mm | Smaller than STD by 0.25mm | For crankshafts that have been machined down by 0.25mm. |

| 0.50mm / .020″ | Second Undersize | Thicker than STD by ~0.250mm | Smaller than STD by 0.50mm | For crankshafts that have been machined down by 0.50mm. |

| 0.75mm / .030″ | Third Undersize | Thicker than STD by ~0.375mm | Smaller than STD by 0.75mm | For crankshafts that have been machined down by 0.75mm. |

Rod Bearing Replacement Cost vs. Prevention

The rod bearing replacement cost can vary, but the parts themselves are relatively inexpensive. However, the cost of getting it wrong is astronomical. A failed rod bearing can destroy the connecting rod, the crankshaft, and even crack the engine block, leading to a complete engine replacement costing tens of thousands of dollars.

The investment in a good micrometer, a service manual, and the time to do the job correctly is minuscule compared to the cost of failure.

Key Takeaways

- Trust the Markings, Not Your Eyes: You can see the size (e.g., STD, 0.25, 0.50) on the back of the bearing shell. This is your only reliable identifier.

- Measure, Don’t Guess: An outside micrometer is an essential tool for this job.

- Verify with Plastigage: This final check ensures your oil clearance is perfect and is your best insurance against failure.

- Remember the Paradox: “Undersize” (US) on the box means a thicker bearing for a smaller crankshaft journal.

At FridayParts, we understand that downtime costs a lot. That’s why we supply a comprehensive range of high-quality, precision-engineered engine components, including a full selection of standard and undersize connecting rod bearings. By following this guide and using the right parts, you can ensure your heavy machinery’s engine lasts, keeping you productive and profitable for years to come. Get the right part, the first time.