Is your excavator seeming to operate with a kind of unusual sluggishness? Does your bulldozer emit blue smoke while bearing a heavy load? Such phenomena generally indicate that there might be an internal complication within the engine, and the true culprit could very well be piston rings that require cleansing. Before proceeding toward a complete engine overhaul, there exists a certain method through which one may attempt to purify and loosen those seized piston rings—without the necessity of removing the pistons themselves. This guide shall lead you through a practical procedure suitable for heavy-duty diesel engines, capable of restoring compression and diminishing oil consumption, thus sparing you thousands of dollars in labor and downtime.

What is an Engine Piston Ring?

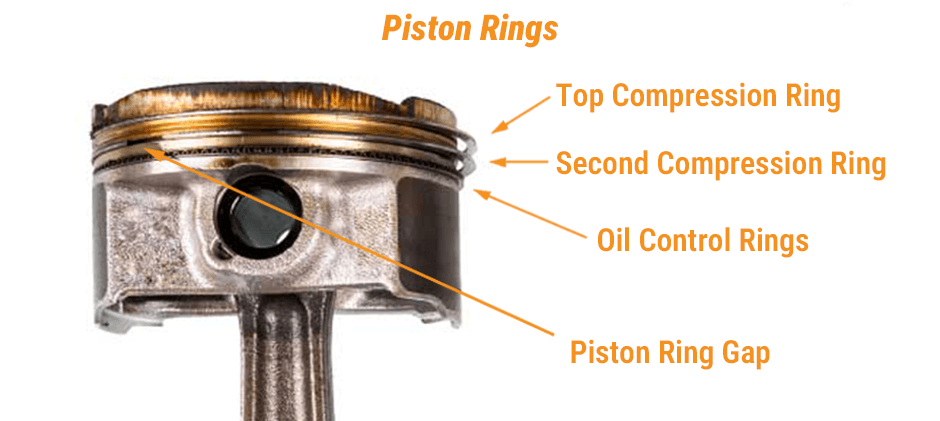

Before one dares to cleanse the piston rings, it is wise to first grasp what they truly are and the crucial duties they perform within the engine’s inner sanctum. Far from being mere metal loops, piston rings are delicately engineered seals vital to an engine’s might, efficiency, and longevity. They dwell within the shallow grooves along the piston’s side.

A typical diesel piston bears several rings, each with its solemn responsibility:

- Top Compression Ring: The chief among them, forming a steadfast seal with the cylinder wall to endure the fierce pressure of combustion, thus granting the engine its full vigor.

- Second Compression Ring: Acting as the sentinel below, it supports the top ring and wipes excess oil from the cylinder wall during the piston’s descent, preventing oil from trespassing into the combustion chamber.

- Oil Control Ring: Residing at the base, it diligently scrapes oil from the cylinder wall and channels it back to the crankcase through its slots or perforations.

- Ring Gap: Each ring bears a subtle opening, allowing for installation and for the metal’s expansion under heat without binding within the cylinder.

How to Clean Piston Rings Without Removing?

It must be expressly comprehended that this procedure applies solely to piston rings that are seized, rather than those fractured or utterly deteriorated. The method employs chemical immersion, whereby the carbon deposits within the cylinder are progressively dissolved.

Disclaimer: This constitutes a task of considerable intricacy. The operator shall at all times conduct the operation within an environment endowed with adequate ventilation and shall don proper protective apparatus, inclusive of gloves and safety goggles.

Step 1: Gather Your Supplies

- Engine Carbon Cleaner/Flush: Choose a high-quality solvent designed for internal engine use in diesel engines. Products like Sea Foam, Berryman B-12 Chemtool, or dedicated diesel engine “unjamming” fluids are common choices.

- Basic Hand Tools: You’ll need wrenches or sockets to remove the fuel injectors or glow plugs.

- Shop Rags: You will need plenty of these.

- Engine Oil and a New Oil Filter: This is not optional. You must change the oil after this procedure.

Step 2: Preparation of the Engine

Commence the activation of the engine until it attains its customary operational warmth, which shall enable the solvent to exert its efficacy with greater proficiency. Thereafter, cease the engine’s motion and permit it to repose for not less than 30 to 60 minutes, to avert the peril of scalding. For the assurance of safety, detach the battery connection.

Step 3: Access the Cylinders

Unlike gasoline engines with spark plugs, on a diesel engine, you will access the cylinders by removing either the fuel injectors or the glow plugs. Glow plugs are generally easier to remove and present less risk of damaging a costly component. Carefully remove one from each cylinder.

Step 4: Apply the Cleaning Solvent

Place the piston at about half of its stroke position (if necessary, you may manually shut down the engine). Through the injector or glow plug opening, pour a proper quantity of cleaning solvent into each cylinder. Normally, each cylinder shall receive about 2–4 ounces (60–120 milliliters), yet it is wise to follow the instructions written on the product.

Step 5: Let It Soak

- This is the step of utmost importance. The glow plug or injector should be screwed back loosely, so as to prevent unwanted debris from entering. Now, patience must be exercised.

- For mild carbon accumulation, a soaking of 8–12 hours shall suffice.

- For severe carbon buildup, allow the engine to soak for 24 to 48 hours. Such duration grants the solvent sufficient time to infiltrate through the dense carbon and release the piston rings.

Step 6: Purge the Cylinders

A critical step of safety: before reassembling any component, all liquid solvent must be expelled from the cylinders. Liquid is not compressible. Attempting to start the engine with fluid remaining inside the cylinders will cause hydraulic lock, bending the connecting rods, fracturing the pistons, and bringing forth catastrophic engine failure.

- Remove the loosely fitted injectors or plugs.

- Cover the openings with a thick cloth to avoid splashing mist.

- Shut off the fuel system to prevent unintended ignition.

- Crank the engine for 5–10 seconds. The pistons shall force out the solvent and the dissolved carbon through the openings.

Step 7: Reassemble and Replace the Engine Oil

After the cylinders are purged, reinstall the glow plugs or injectors, tightening them according to the manufacturer’s specification. Now, drain the old oil, for it has been tainted by the solvent that seeped into the piston rings. Replace the oil filter and refill the engine with fresh oil of the correct grade.

Step 8: Start the Engine

Reconnect the battery and restore the fuel system. Start the engine. During the first few minutes, it may run roughly and emit heavy smoke, for it is burning away the residual solvent and dislodged carbon. Allow it to run at a high idle until the smoke diminishes and operation becomes steady. Run the machine under a light load to confirm improved power and reduced exhaust smoke.

Tips for Cleaning Engine Piston Rings

- Choose Superior Products: One must not fall into the temptation of acquiring cleaning solvents merely for their low price. Those of reputable origin and high quality usually demonstrate greater efficiency and are less inclined to inflict harm upon the inner components of the engine.

- Patience is of the Essence: The effectiveness of this endeavor bears a direct relationship with the duration of solvent immersion. Should one hasten through this step, the outcome shall inevitably fall short of expectation.

- Know When to Cease: Though this chemical cleansing method performs admirably, it is by no means a cure-all. If, after finishing, the problem persists, it likely indicates the issue exceeds just the simple sticking of the piston rings. You may well be confronting severely worn rings, damaged pistons, or scored cylinder walls. In such a case, disassembly and meticulous inspection of engine block parts for wear and damage are required.

- Attend to Subsequent Maintenance: Following the cleaning, one must adhere strictly to the oil replacement schedule and employ only fine-grade engine oil. Clean fuel filter and air filters shall further diminish contaminants that give rise to carbon accumulation.

From a Quick Fix to a Lasting Repair

When the mere simplicity of repair ceases to suffice, a trustworthy companion is required for a true restoration. A complete engine overhaul may appear intimidating, yet it need not drain one’s coffers. FridayParts presents an abundant assortment of superior yet affordably priced aftermarket engine components — from comprehensive piston and ring assemblies to bearings, gaskets, and beyond. Should your needs transcend mere chemical cleansing, seeking instead to reclaim the engine’s original vigor, we possess the very parts indispensable to bringing your restoration to fulfillment.