Water is the enemy of diesel fuel systems. After winter storage, your tank can act like a “mini reservoir” because temperature swings create condensation that ends up in the fuel. This guide explains what a fuel water separator does, the most common water in diesel symptoms, and exactly how to drain water from a fuel separator before spring work begins.

“Clean fuel is power. Water is wear.”

Why Is Water in Diesel Common After Winter?

Condensation is the main reason water shows up in the tank. Warm daytime air enters the tank, cool nights drop the temperature, and moisture condenses on the tank walls and runs down into the fuel.

Half-full tanks make the problem worse. More air space inside the tank means more moisture available to condense into water.

Clear Statement: Winter storage turns small humidity changes into real water accumulation.

What Does a Fuel Water Separator Do?

A fuel water separator removes free water before it reaches the injection system. It uses gravity and a filter element to separate heavier water droplets from diesel and trap debris.

Most separators also act like a primary filter. Many assemblies catch larger contamination first, protecting the finer diesel fuel filter downstream.

“The separator is your first line of defense—don’t skip it.”

7 Symptoms of Water in Diesel Fuel

- Hard starting is the most common early symptom. Water disrupts combustion and reduces fuel quality, especially in cold or damp conditions.

- White smoke can signal poor combustion. White exhaust at startup or under load may happen when water is present, or fuel isn’t atomizing correctly.

- Rough idle points to inconsistent fueling. Water droplets and debris can cause uneven injection events.

- Loss of power under load is a classic complaint. If your tractor is losing power under load, restriction, or water contamination is high on the list.

- Surging or hesitation suggests fuel starvation. A partially blocked element can behave like an intermittent fuel supply.

- Stalling after a few minutes often indicates restriction. As demand increases, a clogged element can’t keep up.

- Rusty or cloudy fuel in a sample is a direct clue. If a drained sample looks milky, you likely have water mixed in.

Clear Statement: If symptoms worsen after sitting all winter, suspect water and filter restriction first.

How Does Water Damage Diesel Engines?

- Water causes corrosion and rust in precision parts. Modern injection systems rely on tight tolerances, and rust can quickly damage pumps and injectors.

- Water can trigger microbial growth (“diesel algae”). Microbes live at the fuel-water boundary and create slime that plugs filters and lines.

- Water reduces lubrication inside pumps and injectors. Diesel provides some lubrication; water does not, which increases wear and scoring.

“Water doesn’t just lower performance—it shortens component life.”

When Should You Drain the Fuel Water Separator?

- Drain it before spring startup and anytime symptoms appear. “Spring first start” is the perfect moment, because that’s when condensation water is most likely to have collected.

- Drain more often if you work in wet, muddy, or humid environments. Frequent temperature swings and questionable fuel storage accelerate contamination.

Clear Statement: Spring is not only planting season—it’s separator season.

6 Steps to Drain Water from a Fuel Separator

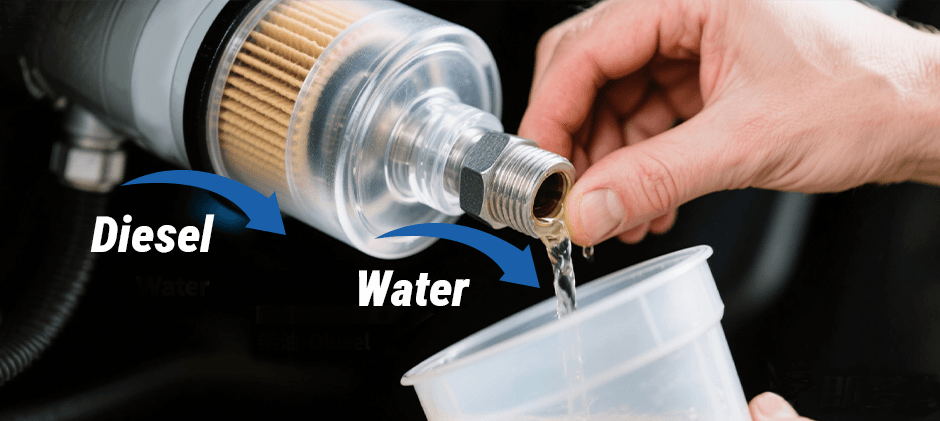

Draining is a quick job, but it must be clean. Use a clear container and keep dirt away from fittings.

Step 1: Park Safely and Shut The Engine Off

Safety prevents accidents. Park the level, set the brake, and let the hot components cool.

Step 2: Clean The Area Around The Separator

Cleanliness prevents new contamination. Wipe dirt off the bowl, drain valve, and housing.

Step 3: Place A Clear Jar Under The Drain

A clear jar helps you confirm water. Water will settle at the bottom and look like a separate layer.

Step 4: Open The Drain Slowly

Slow draining separates layers better. Drain until you see clean diesel with no water layer.

Step 5: Close The Drain And Check For Leaks

Leaks create air intrusion. Air in the fuel line can cause hard starting and rough running.

Step 6: Prime If Your System Requires It

Priming restores fuel flow. Use the hand primer or key-on prime function (model-dependent) until firm, then start.

“Drain until it’s clean, then stop—don’t empty the whole system unnecessarily.”

5 Mistakes That Cause Water in Fuel

Small habits can refill your separator with water. Avoid these common issues:

Mistake 1: Storing With A Low Fuel Level

Low fuel = more condensation space. Keep the tank appropriately filled for storage when recommended by the OEM.

Mistake 2: Using Questionable Fuel Sources

Bad fuel brings water and debris in. Use clean cans, filtered funnels, and reputable suppliers. Check our Heavy Equipment Diesel Fuel Buying Guide for more tips.

Mistake 3: Ignoring Bowl O-Rings And Seals

Bad seals let air and moisture in. Replace cracked O-rings during service.

Mistake 4: Waiting For “No-Start” Before Servicing

Filters usually warn you first. Power loss, surging, and rough idle are early signals.

Mistake 5: Not Replacing The Element When It’s Due

Draining removes water, not plugged media. A restricted element still chokes the flow even after draining. See our guide on how often to change your fuel filter.

Clear Statement: Draining is maintenance; replacing is prevention.

When Should You Replace the Separator Element?

Replace before spring if the machine sat all winter. Many owners intentionally schedule changing the fuel filter before spring because it reduces downtime when work is urgent.

Replace immediately if you find heavy water, slime, or rust. Those signs suggest ongoing contamination and possible microbial growth.

Replace if the tractor loses power under load. Fuel restriction is often filter-related, and filters are cheaper than injectors.

“A new filter is cheaper than one bad day in the field.”

Why Does the Fuel Filter Keep Plugging Up?

Repeated plugging often means the contamination source is upstream. Check tank condition, filler cap seal, venting, and storage containers.

A failing lift pump can mimic filter problems. If you replace filters and still have starvation symptoms, inspect the fuel lift pump and fuel lines for collapse, air leaks, or weak supply.

Clear Statement: If new filters don’t fix it, stop “parts swapping” and inspect the tank, lines, and pump.

What Parts Do You Need for a Reliable Spring Start?

A fresh separator and filter setup is the simplest spring insurance. Off-road machinery owners often choose an aftermarket fuel filter for Kubota/John Deere when they need dependable filtration without OEM pricing delays.

Assemblies and elements solve different problems. If your bowl is cracked or the drain valve leaks, consider a full Fuel Water Separator Assembly; if the housing is fine, an element replacement is enough.

“Replace what leaks. Renew what clogs.”

Final Words

A fuel filter water separator is your spring startup safeguard against water, rust, and power loss. Drain the separator, inspect the fuel sample, and replace the element if there’s any doubt—especially if you notice hard starting, white smoke, rough idle, or a tractor losing power under load. To minimize downtime before spring work, check FridayParts for a replacement fuel water separator (assembly or element options) and consider inspecting related items like the fuel lift pump at the same time.