Modern machinery has that strong power, mostly due to the hydraulic cylinder. They convert pressurized fluid energy into powerful and precise linear motion. To maintain their optimal condition, knowing the hydraulic cylinder components and their function is key. This guide is designed to provide that comprehensive knowledge. We will introduce every critical component, from the main cylinder barrel and piston rod down to the individual seals and wipers, giving you a complete picture of what keeps your machinery working.

What is a Hydraulic Cylinder?

A hydraulic cylinder is a mechanical actuator that uses pressurized hydraulic fluid to produce linear force and motion. It consists of a cylinder barrel, in which a piston connected to a piston rod moves back and forth.

This controlled and powerful back-and-forth movement is the source of nearly every major function on your equipment. It’s what provides the raw strength to lift a fully loaded excavator bucket, the precision to angle the blade on a motor grader, the force to steer a massive articulated dump truck, and the stability to plant a crane’s outriggers firmly on the ground.

Types of Hydraulic Cylinder

While many variations exist, they are primarily categorized by their method of operation.

Single Acting Hydraulic Cylinder

A single acting cylinder uses hydraulic pressure to extend the piston rod in one direction. Retraction is accomplished by an external force, such as gravity or an internal spring. These are simpler in design and are ideal for applications like lifts and presses where force is only needed for one part of the cycle.

Double Acting Hydraulic Cylinder

A double acting cylinder has ports at both ends, allowing hydraulic pressure to extend and retract the piston rod. This provides complete control over movement in both directions, making it the most common type used in construction and agricultural machinery.

How Does a Hydraulic Cylinder Work?

At its core, a hydraulic cylinder works by converting hydraulic fluid pressure into linear motion and force:

- Pressurized fluid enters a port on one side of the piston inside the cylinder barrel.

- The fluid pushes against the piston surface, creating a force that moves the piston and its attached rod.

- This movement directly translates into mechanical action — lifting, pushing, steering, or stabilizing heavy equipment.

- In a double-acting cylinder, fluid can also be directed to the opposite port to pull the piston rod back, ensuring full control of movement in both directions.

Think of it as a simple but powerful cycle: fluid in → piston moves → machine works. This precise yet forceful transfer of energy is what lets an excavator bucket lift tons of material or allows a crane to extend its outriggers smoothly and safely.

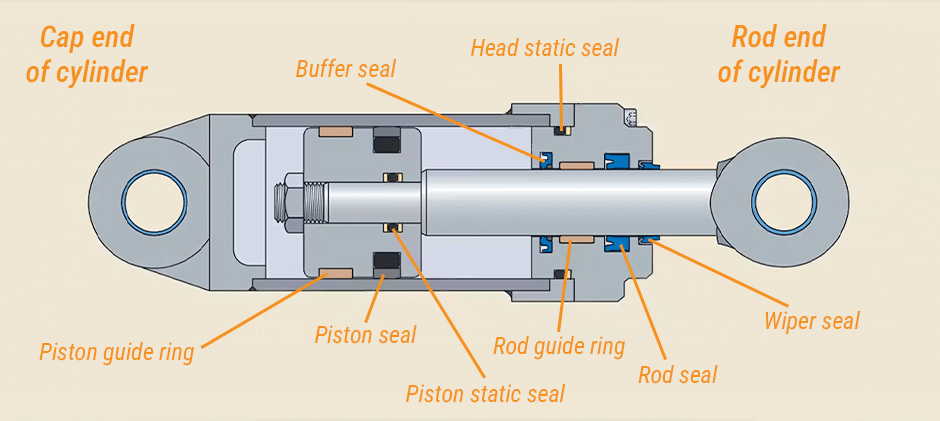

Hydraulic Cylinder Parts Diagram

To properly diagnose and maintain your equipment, it’s essential to know the function of all Hydraulic Cylinder Components. Here they are, explained from the most critical external parts to the internal components.

1. Piston Rod

This is the hard-chromed steel shaft that extends from the cylinder to perform work. It is arguably the most critical component as it is exposed to the elements and physical stress.

- Function: Transfers the force generated inside the cylinder to the machine’s implement.

- Key Feature: A smooth, damage-free surface is essential. Nicks, rust, or bends in the rod will quickly shred the seals, causing leaks and system failure.

2. Seals & Wipers

This group of Hydraulic Cylinder Components is responsible for containing high-pressure fluid and keeping contaminants out. A leaking cylinder is almost always due to a failed seal.

- Rod Seals: Located in the cylinder head, they prevent fluid from leaking externally along the piston rod.

- Wiper Seals: The first line of defense, located at the very edge of the cylinder head. They scrape dirt, water, and debris from the rod as it retracts to prevent contamination.

- Piston Seals: Mounted on the piston, they prevent fluid from bypassing the piston internally, which would cause a loss of power and holding ability.

- Wear Rings (or Guide Bands): Low-friction bands on the piston and in the head that prevent metal-to-metal contact, absorb side loads, and ensure smooth movement.

3. Cylinder Head

The component that closes the rod-end of the barrel. It is a complex part that serves multiple functions.

- Sealing: It houses the critical rod seals and wiper seals.

- Guiding: It provides a bearing surface to guide the piston rod, ensuring it moves in a straight line.

- Variations: Hydraulic Cylinder Heads come in many designs, such as Internally Threaded Heads (TH/TK types) for specific applications or custom-machined units like Bobcat Replacement Heads.

4. Cylinder Barrel

The main body of the cylinder. It is a seamless, heavy-walled tube built to contain extreme pressure.

- Pressure Containment: Its primary function is to safely withstand the maximum operating pressure of the hydraulic system.

- Guide Path: The internal surface is honed to a mirror-smooth finish, allowing the Cylinder Piston to travel efficiently and enabling a tight seal.

5. Piston

The “engine” of the cylinder. This is the cylindrical component that moves back and forth inside the barrel, pushed by hydraulic fluid. It is attached to the piston rod.

6. Cylinder Cap (Base or End Cap)

This part closes the “blind” end of the cylinder barrel (the end opposite the rod). It often contains a fluid Port and frequently incorporates one of the cylinder’s Mounts.

7. Mounts

These are the components that physically attach the entire hydraulic cylinder to the machine. The type of mount determines how the cylinder can pivot and move. Common styles include clevis (a U-shaped bracket with a pin) and trunnion mounts.

8. Ports

The threaded openings in the barrel, head, or cap where hydraulic hoses connect. They allow pressurized fluid to enter and exit the cylinder to control its movement.

9. Hydraulic Cylinder Accessories

These are additional parts for a hydraulic cylinder that enhance its function.

- Collar: Often used as a stop, a mounting feature, or part of a locking mechanism on the cylinder’s exterior.

- Integrated Valves: Some cylinders have valves built directly into them, such as counterbalance or pilot-operated check valves.

Knowing these clear hydraulic cylinder components, you can also easily understand how to rebuild a hydraulic cylinder.

Conclusion

It’s key to knowing thoroughly about the hydraulic cylinders, for diagnosing problems and ensuring the right maintenance and easy replacement. If you find any problems with your hydraulic cylinders, knowing this, you can quickly identify what is going wrong and find the specific parts.

After targeting the problem, you can browse FridayParts.com to get reliable hydraulic cylinders & components quickly at a low price. Besides, we always prepare extensive stocks, whether a hydraulic cylinder head or an end cap, to cater to your demands. Enjoy a quick buy!