Your John Deere 5065E is a capable 65-horsepower utility tractor built for years of reliable service—if you maintain it properly. Following the correct maintenance schedule prevents expensive breakdowns, extends component life, and keeps your tractor performing at its best. This comprehensive guide covers every maintenance interval from daily checks to annual services with part numbers, fluid specifications, and procedures.

The 5065E is part of John Deere’s 5E Series utility tractors, built from 2014-present as mid-range workhorses for farms, ranches, and commercial operations. These tractors feature mechanical front-wheel drive, transmission options including synchro and power reverser, and robust hydraulics. Proper maintenance keeps these systems operating reliably through thousands of hours.

Understanding Maintenance Intervals

John Deere organizes maintenance by service intervals measured in operating hours. Your tractor’s hour meter tracks engine running time—use this to schedule services. When both an hour interval and a time interval are specified, perform maintenance at whichever comes first. A tractor operated 50 hours per year reaches the annual interval before the hour interval; a commercial machine hits hour intervals first.

The 5065E maintenance schedule includes these key intervals:

- Daily or Every 10 Hours – Pre-operation checks

- Every 50 Hours or Weekly – Basic fluid and safety checks

- Every 100 Hours or Quarterly – Lubrication service

- Every 200 Hours or Semi-Annually – Filter and fluid inspections

- Every 400 Hours or Annually – Major filter changes

- Every 800 Hours or Every 2 Years – Transmission and hydraulic service

- Every 1,200 Hours or Every 3 Years – Coolant and major services

Severe service conditions warrant shorter intervals. If you operate in dusty environments, extreme temperatures, with sustained heavy loads, or in commercial applications with long daily hours, reduce service intervals by 25-50%.

Daily/Every 10 Hours Service

These quick checks take 10-15 minutes and catch problems before they cause damage or leave you stranded. Perform them before starting work each day or after every 10 hours of operation.

Engine Oil Level Check

Check engine oil with the tractor on level ground and engine off for at least 5 minutes. Pull the dipstick from the right side of the engine, wipe it clean, reinsert it fully, and pull it again to read. The level should be between the ADD and FULL marks. If it’s low, add the correct oil (15W-40 or Plus-50 II) to bring it to FULL. Don’t overfill.

Low oil level indicates consumption from normal use, leaks, or oil degradation. Check under the tractor for oil spots if the level drops quickly between changes. A quart every 100 hours is acceptable; more indicates problems.

Coolant Level Check

Check the coolant level in the overflow reservoir on the left side of the engine compartment. The level should be between the COLD FILL and HOT marks when the engine is cold. If it’s low, add a 50/50 mixture of John Deere Cool-Gard II and distilled water.

Never open the radiator cap when the engine is hot—pressure and boiling coolant can cause severe burns. If the coolant level drops repeatedly, inspect for leaks at hoses, clamps, the water pump, and the radiator.

Fuel Level and Water Separator

Check the fuel gauge and refill before the tank gets below 1/4 full. Running low allows sediment from the tank bottom to enter the fuel system. After refueling, check the fuel water separator bowl under the hood for water accumulation. If you see water (it settles below the diesel fuel), drain it by opening the drain valve at the bottom of the separator.

Water in diesel fuel comes from condensation in the tank or contaminated fuel. It damages injection pumps and injectors. Always drain water before starting the engine.

Air Cleaner Restriction Indicator

Check the air cleaner restriction indicator on the air cleaner housing. If the red indicator is visible, the air filter needs service. A restricted air filter reduces power, increases fuel consumption, and allows contaminants to enter the engine.

Visual Inspection

Walk around the tractor looking for:

- Fluid leaks (oil, coolant, hydraulic fluid, diesel fuel)

- Damaged or loose components

- Tire condition and pressure

- Loader and three-point hitch operation

- Lights and safety equipment function

- Debris buildup around the engine or the cooling system

Address any issues before operating. A small leak or loose component becomes a major problem if ignored.

Every 50 Hours or Weekly Service

This service interval adds battery maintenance, tire pressure checks, and basic lubrication to the daily checks. Budget 20-30 minutes for thorough completion.

Battery Inspection

Check battery terminals for corrosion, loose connections, and cable condition. Clean corroded terminals with a wire brush and a baking soda solution. Tighten loose connections. Check the battery case for cracks or damage.

If your 5065E has a conventional (serviceable) battery, check electrolyte level in each cell. Add distilled water if needed to cover the plates—don’t overfill. Maintenance-free batteries don’t require water addition.

Tire Pressure

Check tire pressure when tires are cold. Proper pressure for the 5065E depends on tire size and application, but typical pressures are:

- Front tires: 24-30 PSI

- Rear tires: 16-20 PSI

Check your operator’s manual for specific pressures for your tire configuration. Under-inflated tires wear quickly, reduce fuel economy, and affect stability. Over-inflated tires ride rough and reduce traction.

Radiator and Screen Cleaning

Inspect the radiator screen and cooling fins for debris accumulation. Dust, chaff, grass clippings, and dirt block airflow, causing overheating. Clean the screen and blow out cooling fins with compressed air or wash gently with water spray from the engine side out.

Loader Pivot Points

If your 5065E has a loader, check the loader attachment pins and bushings for wear and proper lubrication. Listen for squeaks or grinding during loader operation—these indicate lubrication needs.

Every 100 Hours or Quarterly Service

This is your primary lubrication service covering all chassis and driveline grease points. You’ll need a grease gun loaded with John Deere Multi-Purpose SD Polyurea grease and about 30-45 minutes.

Front Axle Lubrication

The mechanical front-wheel drive (MFWD) system requires regular greasing to prevent wear in the constantly articulating joints.

- Front axle pivot pin – One grease fitting at the center pivot where the front axle attaches to the tractor frame. Pump grease until you see old grease purge from the seals.

- Steering cylinder pins – Two grease fittings where the steering cylinders attach to the axle and frame. Grease until purge.

- Front wheel bearings – One grease fitting on each front hub. Pump 3-5 shots of grease per hub.

- Front drive shaft U-joints – Two grease fittings on the front drive shaft. Pump grease until you see it purge from the bearing caps.

- Front axle knuckles – Two grease fittings per side (four total) at the front wheel knuckles. These are critical—they protect the constantly rotating joints that allow steering and drive power simultaneously. Grease thoroughly until purge.

Three-Point Hitch Lubrication

- Lift arm ball joints – Two grease fittings where the lift arms connect to the rockshaft. Pump grease until purge.

- Leveling crank mechanism – One grease fitting on the leveling crank assembly. Pump 2-3 shots.

- Check chains and stabilizers – Grease the attachment points if they have grease fittings (some use bushings without fittings).

PTO Shaft Lubrication

- PTO shaft splines – Apply grease to the PTO output shaft splines to prevent wear and allow implement driveshafts to slide freely. Wipe off excess grease to prevent attracting dirt.

Drawbar and Hitch

- If your drawbar has grease fittings, lubricate them. Some fixed drawbars use bushings without grease fittings.

Pedal Linkage

Lubricate clutch and brake pedal pivots with grease or light oil, depending on design. This keeps pedals operating smoothly without binding.

Every 200 Hours or Semi-Annual Service

This service adds filter inspections and fluid sampling to the previous intervals. It’s a good time to assess fluid condition and look for developing problems.

Hydraulic Filter Inspection

Locate the hydraulic filter on the right side of the tractor beneath the operator platform. Inspect it for leaks, damage, or debris buildup. Don’t change it yet—the hydraulic filter changes at 400 hours—but inspecting now catches leaks or damage early.

Transmission Filter Inspection

The transmission filter (if equipped as a separate component) should be inspected for external leaks. On some 5065E configurations, the transmission and hydraulic system share a common filter.

Fuel Filter Check

Inspect the fuel filter canister for leaks or damage. Check the fuel water separator for water accumulation and drain if necessary. The fuel filter changes at 400 hours, but checking now prevents unexpected fuel system problems.

Hydraulic and Transmission Fluid Sampling

Pull a fluid sample from the hydraulic reservoir using a clean fluid extraction pump through the dipstick tube. Put a few drops on a clean white paper towel and examine it. You’re looking for:

- Color – Should be amber to light brown and transparent. Dark or opaque fluid indicates contamination or overheating.

- Smell – Should have minimal odor. The burnt smell means overheating.

- Particles – Small amounts of fine metallic dust are normal. Chunks or lots of metal indicate internal wear.

- Water – Milky or cloudy appearance means water contamination requiring immediate fluid change.

If fluid shows problems, change it early, even if you haven’t reached the 800-hour interval.

Belt Tension Inspection

Check the engine drive belts (alternator, fan, and air conditioning if equipped) for proper tension, cracks, fraying, or glazing. Belts should deflect about 1/2 inch under moderate thumb pressure at the longest span. Replace worn or damaged belts before they fail.

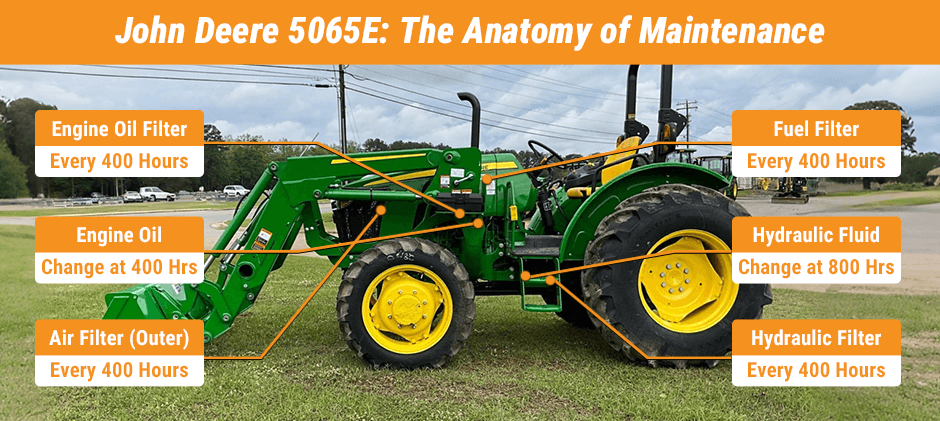

Every 400 Hours or Annual Service

This is a major service interval including engine oil and filter, fuel filter, air filter, and various fluid and component checks. Budget 2-3 hours and gather all necessary parts before starting.

Engine Oil and Filter Change

- Capacity: 8.5 quarts (8 liters) with filter change

- Oil specification: John Deere Plus-50 II 15W-40 or equivalent API CJ-4 diesel engine oil

- Filter part number: RE504836 (oil filter)

Warm the engine by running it for 10 minutes, then shut it off and let it sit for 5 minutes. Position a drain pan under the drain plug on the bottom of the oil pan. Remove the drain plug (19mm socket) and let oil drain completely—this takes 10-15 minutes.

While draining, remove the old oil filter with a filter wrench. It’s on the right front side of the engine. Clean the filter mounting surface on the engine block.

Fill the new filter about half full with clean oil and coat the rubber gasket with oil. Thread it onto the mounting stud by hand until the gasket contacts the block, then tighten an additional 3/4 turn by hand. Don’t use the filter wrench to tighten.

Reinstall the drain plug with a new copper crush washer if available. Tighten to 35-40 ft-lbs—snug but not over-tight.

Fill the engine with 8 quarts of fresh oil through the filler cap on top of the engine. Start the engine and let it idle for 30 seconds, then shut it off and wait 5 minutes. Recheck the oil level and add if needed to bring it to FULL. Check for leaks around the filter and drain plug.

Fuel Filter Replacement

Primary fuel filter part number: RE522688 (spin-on canister with water separator)

Secondary fuel filter part number: RE541925 (if equipped)

The 5065E primary fuel filter is a combination filter/water separator that removes water and particles from diesel fuel before it reaches the injection pump. It’s under the hood on the right side of the engine.

Turn the drain valve at the bottom of the filter bowl to drain fuel and water into a catch container. Once empty, use a filter wrench to remove the entire filter assembly by turning counterclockwise. Clean the mounting surface on the filter head. Fill the new filter about 2/3 full with clean diesel fuel to prime the system. Coat the gasket with clean diesel fuel or light oil.

Thread the new filter onto the mounting head by hand until the gasket contacts, then tighten an additional 1/2 to 2/3 turn by hand. Don’t over-tighten—the gasket seals, not thread torque.

Prime the fuel system by pumping the hand primer on the filter head (if equipped) or by turning the key to the run position without cranking for 30 seconds to allow the electric fuel pump to prime. Crank the engine—it may take a few extra seconds to start as air purges from the system. Check for leaks.

Air Filter Service

Outer element part number: AT171854

Inner element part number: AT171853

The 5065E uses a dual-element dry air filter. The outer element gets dirty and requires regular cleaning or replacement. The inner safety element stays in place and is only replaced every other outer element change (800 hours) or if damaged.

Remove the air filter cover latches and lift off the cover. Remove the outer element carefully without bumping it against the housing (which dislodges dirt into the clean side).

Inspect the outer element for damage—tears, crushed pleats, or degraded seal. If damaged, replace it. If it’s intact, you can clean it with compressed air (blow from inside out at low pressure, under 30 PSI) or replace it. Many operators replace rather than clean because replacement elements aren’t expensive, and cleaning never fully restores filtering.

Inspect the inner safety element. Don’t remove it unless you’re replacing it. If it’s dirty (at 800 hours or if the outer element was damaged), replace it.

Install the new or cleaned outer element, ensuring it seats properly. Reinstall the cover and secure the latches. Reset the air filter restriction indicator by pushing the button.

Hydraulic/Transmission Filter Replacement

Filter part number: AT336140 (standard configuration)

The hydraulic and transmission system on the 5065E shares a common sump and filter. This filter changes every 400 hours along with the engine oil and fuel filters.

The filter is located on the right side of the tractor beneath the operator platform. You may need to remove a side panel for access. Position a drain pan underneath—expect about a quart of oil to spill when you remove the filter.

Use an oil filter wrench to remove the old filter by turning counterclockwise. Clean the mounting surface thoroughly.

Fill the new filter about 1/3 full with clean hydraulic/transmission fluid (Hy-Gard J20D). Coat the gasket with fluid. Thread it onto the mounting stud by hand until the gasket makes contact, then tighten an additional 3/4 turn by hand.

Start the engine and let it idle for one minute while watching the hydraulic filter area for leaks. Shut off and recheck the hydraulic/transmission fluid level, adding if necessary.

Coolant System Check

Inspect all coolant hoses, clamps, and connections for leaks, cracks, or deterioration. Check the radiator for damage or leaks. Test the coolant concentration with a refractometer or hydrometer—it should be 50/50 coolant and water for -34°F freeze protection. If the concentration is off, drain some coolant and add straight coolant or distilled water to correct it.

Electrical System Check

Inspect all wiring harnesses for chafing, damaged insulation, or loose connections. Check safety switch operation: seat switch, neutral start, PTO engagement. Verify all lights work: headlights, taillights, turn signals, and warning lights.

Every 800 Hours or Every 2 Years Service

This major service interval includes transmission and hydraulic fluid change, along with all previous services. This is typically dealer service for most owners, but mechanically capable operators can do it themselves.

Transmission and Hydraulic Fluid Change

- Capacity: Approximately 13.5 gallons (51 liters) total system capacity

- Fluid specification: John Deere Hy-Gard J20D transmission/hydraulic fluid

- Filter: AT336140 (already changed at 400-hour intervals)

The 5065E uses an integrated transmission and hydraulic system with a common reservoir. When you change this fluid, you’re servicing both systems simultaneously.

Warm the tractor by operating for 15 minutes to bring fluid to operating temperature—warm fluid drains faster and carries more suspended contaminants. Park on level ground and shut off the engine.

Locate the drain plug on the bottom of the transmission case (typically rear-center or left side of the case). Position a large drain pan or container with at least 15-gallon capacity. Remove the drain plug and let the system drain completely—this takes 45-60 minutes.

While draining, cycle the three-point hitch up and down several times with the engine off to push fluid from cylinders and lines back to the reservoir. Operate the remote valves if equipped. Move the range selector through all positions.

Once fully drained, reinstall the drain plug with a new crush washer. Tighten to specification (typically 35-40 ft-lbs).

Fill the system through the hydraulic reservoir filler opening (left side of the tractor beneath the operator platform) with fresh Hy-Gard J20D. Fill slowly to avoid overfilling. Use the dipstick to check the level—fill to the FULL mark.

Start the engine and let it idle. Slowly move the range selector through all positions to circulate fluid through the transmission. Operate the three-point hitch and remotes through full range several times to circulate fluid and purge air.

Shut off the engine, wait 10 minutes, and recheck the fluid level. It will have dropped as fluid-filled lines, valves, and cylinders. Add fluid to restore the FULL level. Repeat this process until the level stabilizes.

Inner Air Filter Element Replacement

Replace the inner safety element every 800 hours or every other outer element change. Follow the air filter service procedure above, but remove and replace both elements.

Coolant Testing and Service

Test coolant concentration and condition. If the coolant is more than 2 years old or tests show inadequate corrosion protection or freeze protection, drain and replace the entire system. See the 1,200-hour service below for the coolant change procedure.

Every 1,200 Hours or Every 3 Years Service

This comprehensive service includes coolant system service and a thorough inspection of all major systems. This is typically dealer service.

Cooling System Flush and Refill

- Capacity: Approximately 3.2 gallons (12 liters)

- Coolant specification: John Deere Cool-Gard II

Perform this service when the coolant is more than 3 years old, shows contamination, or tests indicate poor corrosion or freeze protection.

With the engine cold, remove the radiator cap and open the drain cock at the bottom of the radiator. Drain coolant into a catch container for proper disposal—never dump coolant on the ground. Once drained, close the drain cock.

Fill the system with clean water and run the engine until it reaches operating temperature. Shut it off, let it cool, drain the water, and repeat. This flushes contaminants and old coolant residue.

After flushing, fill the system with a 50/50 mixture of Cool-Gard II and distilled water. Don’t use tap water—minerals cause corrosion and scaling. Fill the radiator to the base of the filler neck.

Start the engine and let it warm up to operating temperature with the radiator cap off. This purges air from the system. Watch the coolant level and add as needed as air escapes. Once the thermostat opens and coolant circulates (you’ll see it moving in the radiator), the system is fully bled.

Shut off the engine, let it cool slightly, top off the radiator, and install the radiator cap. Fill the overflow reservoir to the COLD FILL mark.

MFWD Service

Service the front axle differential with fresh gear oil if your 5065E has mechanical front-wheel drive. Some configurations have sealed front axles requiring no service; others have serviceable differentials. Check your operator’s manual.

If serviceable, drain the front axle differential, clean the magnetic drain plug, and refill with John Deere Multi-Purpose GL-5 gear oil (capacity varies by axle model, typically 1-2 quarts).

Comprehensive Inspection

Inspect all major systems thoroughly:

- Clutch operation and adjustment

- Brake operation and adjustment

- Steering system for wear or looseness

- Three-point hitch linkage for wear

- PTO shaft and engagement mechanism

- Loader structure and hydraulic cylinders (if equipped)

- Tire condition and replacement needs

- Seat and operator controls

- ROPS and safety systems

Address any issues found. At 1,200+ hours, your tractor is well broken in, but wear items may need attention.

Severe Service Maintenance

Reduce maintenance intervals by 25-50% if you operate in severe conditions:

- Dusty environments – Change air filters more frequently, inspect the engine breather, and clean the cooling system more often. Consider pre-cleaners or upgraded air filtration.

- High ambient temperatures – Monitor coolant condition closely, change transmission/hydraulic fluid more frequently (heat degrades fluid faster), inspect cooling system regularly.

- Heavy loads or continuous operation – Reduce oil change intervals to 300 hours, monitor transmission/hydraulic fluid temperature, and inspect drivetrain components more frequently.

- Commercial/high-hour use – Follow hour-based intervals rather than time-based. Implement fluid analysis programs to monitor condition and optimize change intervals.

- Extreme cold – Use appropriate winter-grade fluids, inspect the battery and starting system more frequently, and allow longer warm-up periods.

Fluid and Filter Specifications Summary

| Component | Capacity | Specification | Part Number |

|---|---|---|---|

| Engine Oil | 8.5 quarts | Plus-50 II 15W-40 | – |

| Engine Oil Filter | – | – | RE504836 |

| Fuel Filter (Primary) | – | – | RE522688 |

| Air Filter (Outer) | – | – | AT171854 |

| Air Filter (Inner) | – | – | AT171853 |

| Hydraulic Filter | – | – | AT336140 |

| Transmission/Hydraulic Fluid | 13.5 gallons | Hy-Gard J20D | – |

| Coolant | 3.2 gallons | Cool-Gard II 50/50 | – |

| Grease (chassis) | As needed | Multi-Purpose SD Polyurea | – |

Quality aftermarket filters are available from FridayParts at competitive prices. Our filters meet or exceed OEM specifications, protecting your 5065E without the dealer markup.

Maintenance Record Keeping

Keep detailed records of all maintenance performed. Record the date, hour meter reading, services completed, parts used, and any observations or issues noted. This documentation helps you track maintenance history, plan future services, and provides valuable information if you sell the tractor.

Use the maintenance record pages in your operator’s manual, create a simple spreadsheet, or use a dedicated maintenance app. The important thing is consistency—record every service when performed.

Good records also help diagnose problems. If an issue develops, knowing exactly when fluids were changed, what filters were installed, and what services were performed helps with troubleshooting.

Common 5065E Maintenance Issues

- Oil consumption – Some 5065E engines consume oil between changes. A quart every 100-150 hours is within normal limits. More than this indicates worn rings, valve guides, or turbo seals requiring professional service.

- Hydraulic leaks – The three-point hitch lift cylinders and loader cylinders develop seal leaks over time. Small seepage is normal; active dripping requires seal replacement. Keep fittings tight and replace hydraulic hoses showing wear or damage.

- MFWD noise – Front axle knuckles and U-joints make noise when lubrication is inadequate. Stay on top of the 100-hour greasing schedule. If noise persists after proper greasing, the joints may be worn and need replacement.

- Charging system issues – Battery condition and alternator belt tension are common issues. Keep battery terminals clean and tight, maintain proper belt tension, and test the charging system annually.

- Fuel system air – If the engine is hard to start or runs rough after sitting, check for air entering the fuel system through deteriorated fuel lines, loose fittings, or a damaged fuel filter seal.

Frequently Asked Questions

Can I use synthetic oil in my 5065E?

Yes, you can use synthetic 15W-40 diesel engine oil meeting API CJ-4 or later specifications. Synthetic oil provides better protection in extreme temperatures and extended drain intervals, but follow the same 400-hour change interval unless you implement an oil analysis program confirming safe extension.

What happens if I miss a service interval?

Perform the missed service as soon as possible. One slightly late service won’t destroy your tractor, but don’t make it a habit. Consistently delayed maintenance causes accelerated wear and eventual component failure. If you’re significantly overdue (50+ hours past the interval), consider shortening the next interval to compensate.

Can I use Hy-Gard J20C instead of J20D?

J20D (low-viscosity Hy-Gard) is specified for the 5065E transmission and hydraulics. J20C is the standard viscosity formula designed for older tractors. Using J20C may cause sluggish hydraulic response and harder shifting in cold weather. Use J20D as specified.

How do I know if I need severe service intervals?

If you operate in dusty conditions, high temperatures, with sustained heavy loads, or accumulate more than 500 hours annually, use severe service intervals. When in doubt, shorter intervals provide better protection and aren’t significantly more expensive than repairing worn components.

Do I really need to use John Deere 5065E fluids and filters?

John Deere fluids are formulated to meet specific requirements for their equipment. Quality aftermarket equivalents meeting the same specifications work fine and save money. Avoid no-name economy fluids and filters—they may not meet performance requirements. FridayParts offers quality alternatives at better prices than dealer parts.

Following the proper maintenance schedule keeps your John Deere 5065E operating reliably for decades. Regular service prevents expensive repairs, maintains resale value, and ensures your tractor is ready when you need it. FridayParts stocks filters, fluids, and maintenance parts for your 5065E at prices that make sense. From filters to service kits, we’ve got what you need to maintain your John Deere properly.