When you are working against the clock to reap the crops or to level the ground of a construction site, the headlights of the equipment are regarded as the primary safeguard instrument. Dim and yellowish beam will bring forth fatigue to the eyes, conceal perilous hindrances, and also diminish the overall velocity of operation. For many years, the halogen bulb has been kept as the standard of the trade, yet at present, the LED technology is already pervading everywhere. If you are pondering upgrading or substituting the extinguished bulb, you must make one decisive selection: LED vs halogen? This guide shall dissect their crucial disparity in the domains of performance, durability, and expenditure, thus assisting you to comprehend which headlight technology is more befitting for the harsh circumstances of off-road machinery.

What are LED & Halogen Headlights?

Before diving into the specifics, it’s important to understand the two main technologies competing for the top spot in heavy equipment lighting. They generate light in fundamentally different ways, which directly impacts their performance in the field.

What is an LED Headlight?

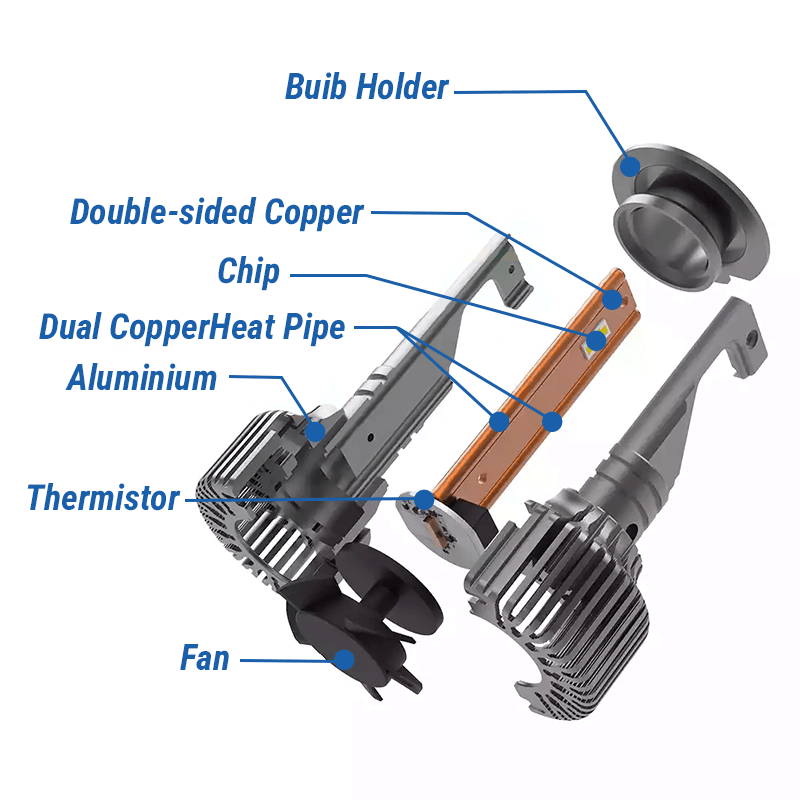

LED (Light Emitting Diode) headlight belongs to one kind of modern lighting technology, which, by means of a solid-state process, gives forth light, without the fragile components inside traditional bulbs that are easy to damage.

- Solid-State Design: LED differs from the conventional bulb; it is one solid-state electronic element, with no moving part, no easily broken glass, and no filament prone to fracture. The entire device is usually sealed inside a durable enclosure and is accompanied by a strong lens.

- Main Characteristics: LED is famous for its high efficiency, high durability, and high-quality light. It transforms most of the energy into light, producing almost no heat. This solid-state design itself brings ability.

What is a Halogen Headlight?

A halogen headlight is the traditional bulb technology that has been standard in vehicles for decades, operating on a simple principle.

- Halogen cycle: Inside the shell is a halogen gas, which is capable of absorbing the tungsten atoms evaporated from the filament and then re-depositing them back. This cyclical process is making the attenuation of filament, thereby making the bulb brighter and more durable than the ordinary incandescent bulb.

- Key Characteristics: The primary advantage of a halogen bulb is its low cost and simple technology. Nevertheless, during the circumstances of off-road driving, its greatest weakness is the fragile tungsten filament, which is exceedingly easy to damage from vibration and collision.

Complete Comparison of LED vs Halogen Headlight

When you place these two technologies side-by-side in the context of a demanding agricultural or construction environment, the differences become stark. The choice is about more than just brightness; it’s about durability, efficiency, and long-term cost.

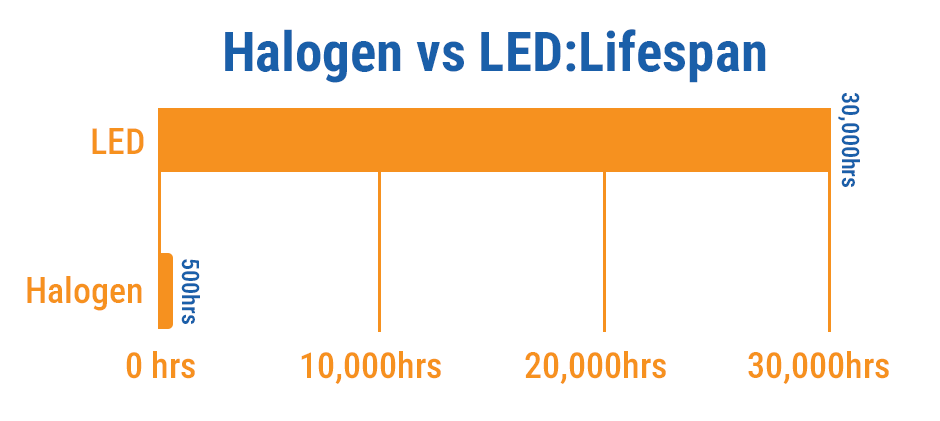

LED vs Halogen Headlight: Lifespan

For the owners of off-road equipment, this is without doubt the most crucial factor. The downtime caused by the failure of headlights not only brings frustration but also produces high costs.

- Halogen: The typical lifespan of halogen bulbs is 500 to 1,000 hours. However, this number is calculated under the condition of ideality. On heavy machinery that is in constant vibration and bearing impact, the fragile tungsten filament may break even before it burns out. It is not a rare matter that one needs to replace halogen work lights several times within a single season.

- LED: The rated lifespan of LED headlights is 30,000 to 50,000 hours. As a solid-state device with no moving parts or fragile filament, it resists impact and vibration extremely well. For the majority of machines, the high-quality LED upgrade becomes an “install once, then forget” solution, and its lifespan is very likely to exceed even the lifespan of the machine itself.

LED vs. Halogen Headlights: Energy Consumption

On heavy machinery running multiple electronic systems, from GPS monitors to hydraulic controls, managing the electrical load is crucial. This is where LED technology has a massive advantage.

- Halogen: The halogen bulb, regrettably, demonstrates an exceedingly deficient efficiency. Merely about 20% of its energy expenditure transmutes into luminous emission, whilst the remaining 80% dissipates futilely in the guise of thermal radiation. Such surplus heat not only imposes a continuous encumbrance upon the bulb housing and circuitry but likewise persists in depleting the alternator’s electrical provision.

- LED: In striking contrast, the LED reveals an inverse disposition. It transmutes beyond 80% of its energy expenditure into light, with less than 20% surrendered as heat. Consequently, under equivalent wattage, the luminous output of the LED approximates three to four times that of the halogen bulb. For the machinery operator, this denotes a reduced encumbrance upon the alternator, heightened stability of the electrical architecture, and the consequent availability of greater usable power for ancillary critical components.

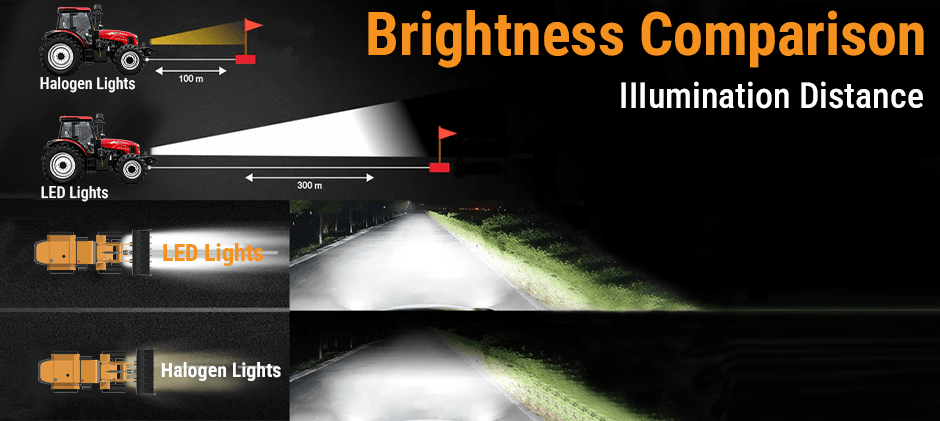

LED vs. Halogen Headlight Lights: Light Distance

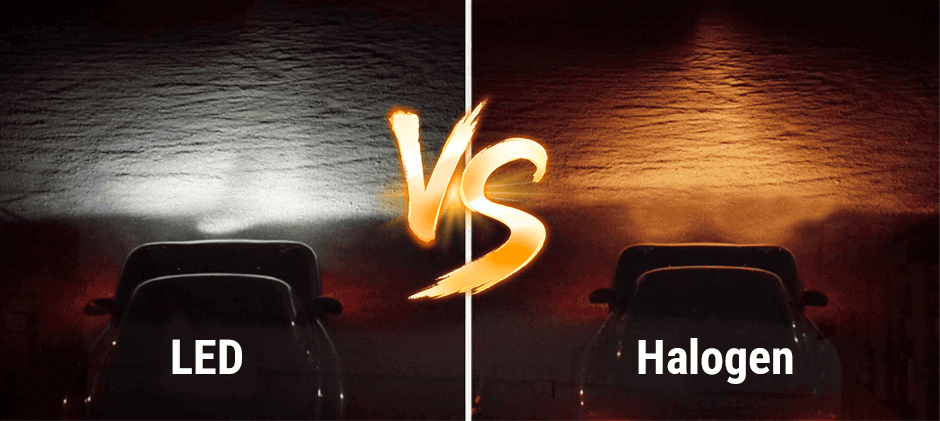

The most immediately noticeable difference when you upgrade from halogen to LED is the quality and reach of the light.

- Halogen: The conventional halogen bulb produces a luminescence inclined toward a yellowish tone, with a color temperature of approximately 3200 Kelvin (K), while its effective projection commonly remains near 100 meters. Such luminous quality frequently renders colors faded in perception, and in the circumstance of protracted nocturnal operation, may exert severe strain upon the ocular faculties of the operator. The limited distance signifies an insufficiency of temporal margin for adequate reaction toward distant field boundaries or obstacles within the construction environment.

- LED: By contrast, a high-quality LED headlight generates a luminance of purer and whiter character, with color temperature typically ranging between 5000K and 6000K, approximating the properties of natural daylight. This condition permits an operator to distinguish with greater facility the chromatic and textural aspects of the working domain. Furthermore, the concentrated and intensive beam of LED radiance extends its effective reach up to 300 meters or more. For tractor operators, this signifies a capability to apprehend the terminal limits of the field with increased rapidity, thereby acquiring supplementary temporal allowance to discern latent hazards, such as stones or erosive formations.

The superior luminous essence and projection distance of LED lighting are not merely ornamental indulgence; they directly contribute toward the mitigation of operator fatigue and the elevation of operational safety.

Halogen vs LED Headlight: Market Trend

The trend in the lighting industry is clear and irreversible. While halogen bulbs remain available due to their low cost, they are considered legacy technology. Today, nearly all new agricultural and construction equipment from major manufacturers comes standard with LED lighting. The aftermarket is following suit, with a massive shift toward LED upgrade kits for older machines. Frequent replacement of consumables like LEDs can easily drain a large budget. FridayParts’ aftermarket headlights offer high-quality, budget-friendly options, eliminating any concerns about price and quality.

How to Choose the Right One?

The evidence overwhelmingly points to LED as the superior technology. The question then becomes not if you should choose LED, but which LED headlight to choose. Here are the key features to look for when making your selection.

| Feature | What to Look For | Why It Matters for Off-Road Machinery |

|---|---|---|

| Lumen Rating | High “Effective” Lumens | Don’t be fooled by “raw” lumens. Effective lumens measure the actual light output after accounting for optical and thermal losses. This is the true measure of brightness. |

| IP Rating | IP67 or Higher | This rating guarantees the light is completely sealed against dust ingress and can be submerged in water. It’s essential for withstanding pressure washing and muddy conditions. |

| Build Quality | Die-Cast Aluminum Housing | A robust metal housing provides armor and heat dissipation, ensuring the LED chips’ durability and longevity. |

| Lens Material | Polycarbonate | A polycarbonate lens is virtually shatterproof, protecting the headlight from impacts from rocks, branches, and other debris. |

| Beam Pattern | Flood or Combo Beam | A “flood” beam provides wide, even illumination of the immediate work area. A “combo” beam offers both a flood pattern and a “spot” pattern for long-distance visibility. |

When you’re ready to upgrade, you don’t have to pay the premium prices charged by equipment dealers for OEM parts. The aftermarket offers a huge advantage. A high-quality aftermarket LED work light can provide the same, if not better, durability and performance as an OEM part at a fraction of the cost. Finding the right light for your specific model is key, and a good supplier will have a vast inventory to ensure compatibility.

Ready for a Brighter, More Durable Future?

For any application of off-road in a serious manner, the technology of LED is showing superiority in every aspect: it shines brighter, it endures longer, and it consumes less energy. Although the cost in the beginning stands higher than that of a single halogen, the value in the long run cannot be doubted. The upgrading to LED requires less frequent replacement, decreases the burden upon the electrical system, and provides the operator with a working environment that is both safer and easier. FridayParts possesses an abundant stock of lights, which are broadly compatible with all mainstream brands of heavy equipment, so you may discover for your machine the upgrading solution that is perfect and also economical. Do not waste any longer!