When the P0012 code appears on your diagnostic scanner, it can stop operations for trucks, excavators, or other off‑road machinery. This code signals improper camshaft timing, which can lead to power loss, unstable idling, and fuel inefficiency—costing hours of downtime. Don’t worry—by the end of this article, you’ll know exactly what the P0012 code means, what’s causing it, how to diagnose it, and how to fix it efficiently.

What Does the P0012 Code Mean?

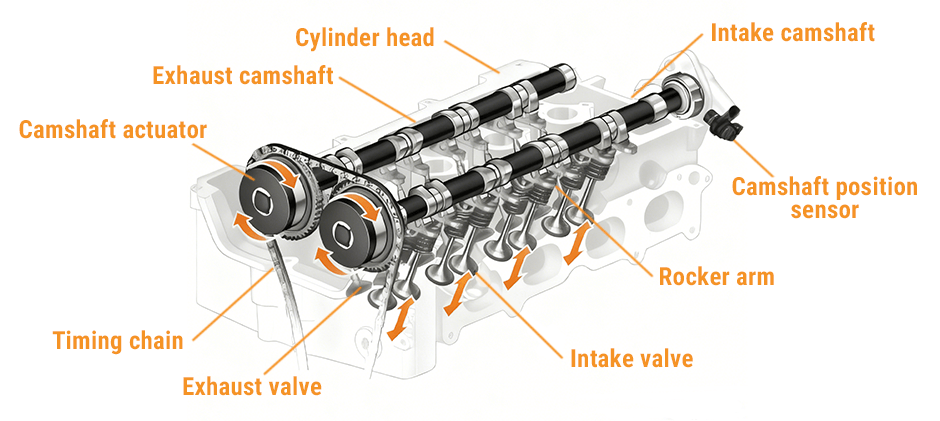

The Diagnostic Trouble Code (DTC) P0012 stands for: “Camshaft Position ‘A’ – Timing Over‑Retarded (Bank 1).”

This means that the intake camshaft on Bank 1 is operating behind the desired timing specified by the Engine Control Module (ECM). In simpler terms, the ECM commanded the camshaft to open earlier, but it responded too late.

How Does it Work Internally?

In off‑road diesel engines, the Variable Valve Timing (VVT) or Variable Camshaft Timing (VCT) system adjusts the camshaft position relative to the crankshaft. This synchronization ensures the correct amount of air and fuel enters the combustion chamber at the precise moment for optimal torque and clean emissions.

When the camshaft becomes “over‑retarded,” valves open too late in the engine cycle, leading to:

- Poor combustion

- Incomplete fuel burn

- High particulate and NOx emissions

- Noticeable power reduction

This situation forces the ECM to trigger the P0012 code and, in many cases, activate emission derate or limp modes to prevent internal damage.

Note: “Bank 1” is the side of the engine containing Cylinder #1. The “A” camshaft refers to the intake camshaft.

What Causes the P0012 Code?

Unlike passenger vehicles, off‑road machines face extreme dust, load, and long‑hour operation cycles. Thus, their lubrication and timing systems undergo severe stress.

Below are the most likely root causes of a P0012 fault in heavy‑duty diesel engines:

| Cause | Mechanism of Failure | Typical Evidence |

|---|---|---|

| Low or Contaminated Engine Oil | Insufficient pressure prevents the oil‑driven VVT actuator from advancing cam timing | Dirty oil, clogged filters, slow oil pressure response |

| Improper Oil Viscosity | Oil that’s too thick or too thin cannot pass through narrow actuator channels quickly enough | Occurs after incorrect oil replacement or cold starts |

| Failed Camshaft Timing (VVT) Solenoid | The solenoid controlling timing adjustment gets stuck with sludge or carbon deposits | Delayed valve responses, P0012 code after idling |

| Worn/Loose Timing Chain | Excess mechanical slack alters base cam‑to‑crank synchronization | Rattling noise at startup or under load |

| Faulty Camshaft Phaser / Actuator | The phaser mechanism locks in retarded position | Rough idle and power loss at mid‑range RPM |

| Clogged Oil Control Valve (OCV) Filter | Gummed‑up oil passages reduce actuator range | Engine hesitation, code recurring after oil change |

| Electrical or Sensor Fault | A failing camshaft position sensor or poor ground signals mislead the ECM | Incorrect timing data, extended crank time during startup |

| Incorrect Assembly or Maintenance | Recent mechanical work (e.g., rebuilt cylinder head) with misaligned timing marks | Immediate reappearance of P0012 code after service |

When multiple factors combine — for instance, thick oil and a partially clogged solenoid — the timing deviation can exceed 12°–15°, enough for the ECM to log code P0012.

Common Symptoms of the P0012 Code

Recognizing symptoms early can prevent extensive engine repair costs. Here’s what operators often notice when P0012 is active in heavy‑duty or off‑road equipment:

- Check Engine Light or Warning Lamp – Indicates a stored DTC (Diagnostic Trouble Code).

- Hard Starting or Rough Idling – The Engine hesitates to start or idles unevenly.

- Reduced Power or Torque Loss – Noticeable during heavy loads or uphill operations.

- Excessive Fuel Consumption – Late valve timing burns more fuel than needed.

- Metallic Rattling or Knocking Sounds – Typically from a stretched chain or failing camshaft phaser.

- Regeneration / Emission Faults – In advanced diesel systems, wrong timing disrupts DPF regen cycles and raises NOx output.

What Repairs Can Fix the P0012 Code?

Before replacing major parts, start with simple, high‑return maintenance steps. Many P0012 cases stem from lubrication issues.

1. Change or Refill Engine Oil

- Use oil with the manufacturer‑specified viscosity (e.g., 15W‑40 for most heavy‑duty diesels).

- Drain old oil completely and replace filters.

- Clean oil passages when possible; sludge can slow VVT actuators.

2. Inspect or Replace the Camshaft Timing Solenoid / VVT Actuator

- Locate the VVT solenoid near the camshaft cover.

- Remove and check for clogging.

- Clean with valve cleaner and test resistance using a multimeter (typically 6–12 Ω).

- Replace if it shows no movement or out‑of‑range resistance.

3. Check Timing Chain and Tensioner

- Inspect for slack or rattle during cold start.

- Replace worn chains, guides, or sprockets if the delay exceeds the manufacturer’s tolerance.

4. Replace or Service the Camshaft Phaser

- A failed phaser may get stuck in a retarded position. Replacement restores accurate timing.

5. Check Electrical Connections

- Examine wiring for oil contamination or corrosion.

- Ensure connectors to the camshaft position and crankshaft sensors are tight.

When components like camshaft assemblies, crankshaft units, or oil control systems need replacement, using reliable aftermarket parts can dramatically reduce downtime and cost.

FridayParts supplies OEM‑grade camshafts and engine rebuild kits compatible with Kubota, Deutz, Cummins, and Caterpillar engines—ideal for excavators, tractors, loaders, and trucks.

How to Diagnose the P0012 Code?

A professional mechanic or experienced operator can follow this process:

Step 1 – Scan and Confirm Codes

Use a diagnostic scanner that supports off‑road engine protocols (SAE J1939). Document all active and pending codes. If you see both P0012 and P0011, it suggests erratic cam timing control.

Step 2 – Check Oil Condition and Pressure

Inspect oil level and clarity:

- Low or dark oil = change immediately.

- Test oil pressure using a mechanical gauge. Low pressure (< 35 psi at operating temp) means restricted or worn pump passages.

Step 3 – Visual Inspection

Remove the valve cover. Look for:

- Metal shavings around cam lobes.

- Worn lobes or journals on the camshaft.

- Carbon buildup is blocking oil galleries.

Step 4 – Electrical Testing

Use a multimeter to test:

- VVT solenoid power supply.

- Camshaft position sensor signal waveform (should alternate cleanly between 0–5 volts).

- Compare readings between Bank 1 and Bank 2 (if applicable).

Step 5 – Mechanical Alignment Check

If suspicion remains, manually check timing marks between cam and crankshaft components. Misalignment, even by one tooth, can cause a P0012 trigger.

| Diagnostic Step | Tool Required | What It Detects |

|---|---|---|

| OBD/Engine Scanner | Code Reader | Confirms fault presence |

| Mechanical Gauge | Oil Pressure Test | Identifies lubrication issues |

| Multimeter | Electrical Test | Checks sensor circuit integrity |

| Borescope / Visual | Inspection | Finds chain slack or contamination |

Common Mistakes When Diagnosing the P0012 Code

Even professionals can overlook small details. Avoid these common pitfalls:

- Skipping the Oil Inspection – Most P0012 cases are oil‑related, not sensor‑related.

- Replacing Sensors First – Always verify oil pressure before replacing the camshaft position sensor.

- Ignoring Electrical Grounds – Rust or loose grounds near the ECM create false timing signals.

- Misreading the Bank Location – On many V‑type engines, Bank 1 refers to the left or driver’s side, depending on layout.

- Not Resetting Adaptation Values – After replacing timing components, reset the ECM’s valve timing parameters.

Finially Words

A P0012 code may seem technical, but it tells a simple story — your engine’s timing has fallen behind. In heavy‑duty and off‑road machinery, that story ends in lost fuel efficiency, climbing emissions, and profit loss unless acted upon quickly. By restoring clean oil flow, recalibrating sensor systems, and replacing worn timing components with OEM‑quality parts from FridayParts, you ensure your engines regain full combustion efficiency and stable working hours in any terrain.