When your machine won’t crank or start, the starter motor is often the main suspect. In heavy equipment, they are designed for high torque and rugged conditions—but their location always follows one rule: they must engage directly with the engine’s flywheel.

This quick guide explains how to find the starter motor location on excavators, loaders, dozers, tractors, and other off‑road machines.

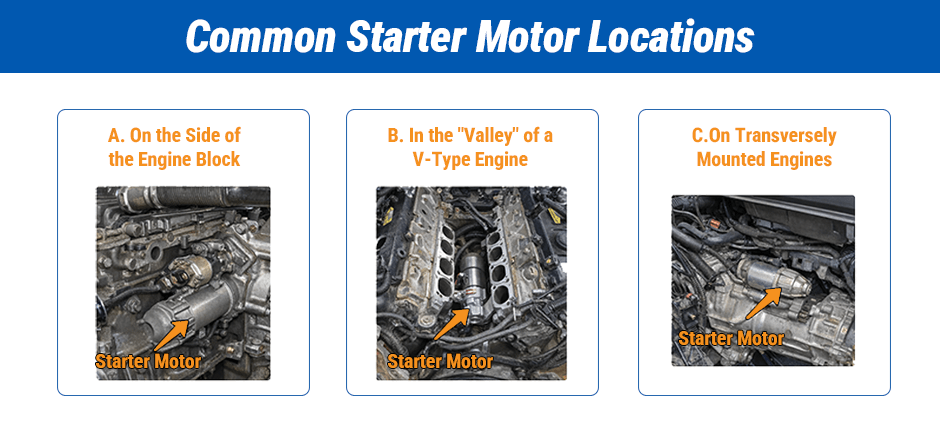

Common Starter Motor Locations

The starter motor is always mounted at the point where the engine connects to the transmission or hydraulic pump housing (bell housing). That’s because it needs to spin the flywheel or flexplate to start the engine. Depending on your machine’s engine type, the starter is typically in one of these three places:

A. On the Side of the Engine Block (Most Common)

Applies to: Inline‑4, Inline‑6, and many V‑type engines (e.g., excavators, wheel loaders, bulldozers).

- What to look for: A cylindrical motor, about 4–8 inches in diameter, bolted near the bell housing on the engine block.

- How to spot it: Check both sides of the engine where it widens toward the transmission or pump housing.

The starter is often on the side away from the exhaust manifold (the “cold side”).

(Note: Some large industrial inline and V engines may mount the starter externally for easier service access or cooling.)

B. In the “Valley” of a V‑Type Engine

Applies to: Larger engines (V‑8, V‑12, V‑16) found in machines from Caterpillar, Komatsu, and others.

- What to look for: The starter is located between the two cylinder banks, under the intake manifold.

- How to spot it: Look from the top — you may only see the back of the solenoid and connecting wires.

Access often requires removing the intake manifold and related components.

(Some V‑type engines place the starter outside the valley for heat management or service clearance.)

C. On Transversely Mounted Engines (Compact Equipment)

Applies to: Skid steers, mini‑excavators, compact tractors, and small loaders.

- What to look for: The starter is bolted to the front or rear face of the engine’s bell housing.

- How to spot it: Access may be through side panels or by tilting the cab. Look for a compact motor with heavy‑gauge wires attached.

How to Locate the Starter with Certainty

If a visual scan isn’t enough, use this reliable method:

Step 1: Safety First

- Park on a level surface and lower all attachments.

- Engage the parking brake and shut off the engine.

- Turn off the master battery disconnect and remove the negative (-) cable.

Heavy‑equipment batteries carry huge current—never skip this safety step.

(Wait at least 30 seconds after disconnecting power to allow capacitors in control modules to discharge.)

Step 2: Follow the Thickest Red Cable

- Start at the battery and find the thickest red cable — usually as wide as your thumb.

- Trace it carefully through the machine; it leads directly to the starter solenoid.

- Where that cable terminates, you’ve found your starter motor.

Step 3: Identify the Assembly

A starter assembly includes:

- Main Motor: Large cylindrical housing.

- Solenoid: A Smaller cylinder on top with one thick and one small wire attached.

Once you see this setup, you know you’ve located the starter.

Accessibility Levels

| Access Level | Typical Time | Description |

|---|---|---|

| Easy | < 1 hour | Starter visible behind a side engine panel |

| Moderate | 1–3 hours | May need to remove belly pans or hydraulic lines |

| Difficult | 3–6 hours | Starter buried in V‑engine valley; requires manifold and fuel‑system removal |

Always refer to your machine’s service manual for brand‑specific steps. The time required will also depend on your familiarity with the process, which our complete starter motor replacement guide can help with.

Final Takeaway

Once you understand how the starter motor connects to the flywheel, you can quickly identify its position on any heavy equipment engine.

Use the “follow the cable” method for fast, safe, and reliable identification—whether you’re diagnosing failure or planning a replacement. For reliable replacement parts, explore starter motors built specifically for off‑road and heavy‑duty applications.