Connecting implements to your tractor should be straightforward, but quick-hitch compatibility and rear remote hydraulic systems can be confusing. Understanding three-point hitch categories, quick-hitch standards, hydraulic coupler types, and flow requirements ensures your implements attach properly and operate safely. This comprehensive guide covers everything you need to know about quick-hitch and rear remote compatibility preventing expensive mistakes and unsafe conditions.

Whether you’re connecting a rotary cutter, box blade, post hole digger, backhoe, or any hydraulically-powered implement, knowing compatibility keeps you safe and productive.

Three-Point Hitch Category System

The foundation of implement compatibility is the three-point hitch category system standardized by ASAE (American Society of Agricultural Engineers). This system defines hitch dimensions, pin sizes, and lift capacity.

Category 0 (Cat 0)

Typical tractors: Sub-compact and compact tractors under 25 HP

Common models: John Deere 1025R, Kubota BX series, Massey Ferguson GC1700 series

Lower link pin diameter: 5/8 inch (16mm)

Lower link spacing: 20.5-24 inches adjustable

Top link pin diameter: 5/8 inch (16mm)

Typical lift capacity: 500-800 lbs at 24 inches behind lift points

Category 0 is the smallest standardized hitch used on garden tractors and sub-compact tractors. Implements are proportionally sized for light-duty work: small tillers, finish mowers, lightweight box blades, and small seeders.

Category 1 (Cat 1)

Typical tractors: Compact and utility tractors 20-60 HP

Common models: John Deere 3000 series, Kubota L series, New Holland Workmaster series, Massey Ferguson 1700M and 2700M series

Lower link pin diameter: 7/8 inch (22mm)

Lower link spacing: 27.25-31 inches adjustable

Top link pin diameter: 7/8 inch (22mm)

Typical lift capacity: 1,600-2,500 lbs at 24 inches behind lift points

Category 1 is the most common hitch for small farms, estates, hobby farms, and commercial landscaping. The vast majority of utility and compact tractors use Cat 1 hitches. Implement selection is enormous—rotary cutters, finish mowers, tillers, box blades, rear blades, spreaders, sprayers, seeders, disc harrows, and hundreds more.

Category 2 (Cat 2)

Typical tractors: Utility and agricultural tractors 50-150 HP

Common models: John Deere 5000-6000 series, New Holland T4 and T5 series, Massey Ferguson 4700-5700 series, Kubota M series

Lower link pin diameter: 1-1/8 inch (28.5mm)

Lower link spacing: 31-36 inches adjustable

Top link pin diameter: 1-1/8 inch (28mm)

Typical lift capacity: 3,500-6,000 lbs at 24 inches behind lift points

Category 2 serves agricultural and commercial applications requiring heavier implements: large rotary cutters, heavy disc harrows, chisel plows, balers, heavy-duty box blades, and commercial mowers.

Category 3 (Cat 3)

Typical tractors: Agricultural tractors 100+ HP

Common models: John Deere 7000-8000 series, New Holland T6-T7 series, Case IH Maxxum and Magnum series

Lower link pin diameter: 1-1/2 inch (37mm)

Lower link spacing: 36-44 inches adjustable

Top link pin diameter: 1-1/4 inch (32mm)

Typical lift capacity: 8,000-12,000+ lbs at 24 inches behind lift points

Category 3 handles heavy agricultural equipment: large plows, heavy discs, commercial mowers, large rotary cutters, and implements requiring substantial lift capacity.

Limited Category (Hybrid Systems)

- Category 1N (narrow): Cat 1 pin sizes with narrower link spacing for compact tractors

- Category 1W (wide): Cat 1 pin sizes with wider spacing approaching Cat 2

- Category 1/2: Tractors that can be configured for either Cat 1 or Cat 2 using adapter bushings and link extensions

Some tractors and implements use hybrid or adjustable systems. These require careful measurement and sometimes adapters to ensure proper fit.

Quick-Hitch Systems and Compatibility

Quick-hitches (also called quick-couplers or quick-attach systems) simplify implement attachment by eliminating the need to manually align and pin each of the three hitch points. Instead, you position the implement, back up to it, and engage a single lever or handle to lock all three points simultaneously.

Standard Frame Quick-Hitch

This is the most common type for Cat 1 and Cat 2 tractors. The quick-hitch mounts permanently to your tractor’s three-point hitch. Implements attach to the quick-hitch frame instead of directly to the tractor.

Advantages:

- Fast implement changes (60 seconds vs 10 minutes manual hitching)

- No need to leave the seat for most implements

- Consistent attachment geometry

- Safer—less time working near moving tractor and heavy implements

Disadvantages:

- Adds weight (50-100 lbs)

- Raises implement attachment point slightly (affects implement level)

- Reduces effective lift capacity by 5-10%

- Costs $200-500 depending on category

- Implements need quick-hitch compatible mounting

Compatibility considerations:

The quick-hitch must match your tractor’s hitch category. A Cat 1 quick-hitch uses 7/8-inch pins to attach to a Cat 1 tractor. The implement then attaches to the quick-hitch using the same Cat 1 pin sizes.

Most modern implements come with quick-hitch compatible mounting—they have flat plates or ears with holes matching the quick-hitch spacing and pin size. Older implements may need modification or adapter plates.

Popular brands:

- Pat’s Easy Change (common, well-regarded, widely compatible)

- County Line (Tractor Supply house brand, budget option)

- Speeco (mid-range pricing, good quality)

- Titan Attachments (economy option)

- John Deere iMatch (premium, brand-specific geometry)

Universal compatibility warning: Not all quick-hitches are identical. While they follow category standards for pin size and general dimensions, the exact positioning of implement mounting points varies slightly between brands. An implement designed specifically for one brand’s quick-hitch may not fit another brand’s without minor modification (drilling new holes, using spacers).

For best compatibility, either:

- Buy implements and quick-hitch from the same manufacturer

- Buy implements with universal mounting (multiple hole positions)

- Be prepared to drill new holes or fabricate adapter plates

Bucket-Mount Quick-Attach

Front loader buckets use a different quick-attach system—typically the SSQA (Skid Steer Quick Attach) standard or proprietary systems.

SSQA (Skid Steer Quick Attach):

This standardized system allows implements designed for skid steers to attach to tractor loaders equipped with SSQA mounting plates. The interface uses two hook plates and hydraulic locking pins.

Universal SSQA dimensions:

- Hook plate width: 11.5 inches

- Hook plate spacing: 7.5 inches

- Pin hole spacing: 11.5 inches

- Pin diameter: 3/4 inch

Most modern compact and utility tractor loaders can be retrofitted with SSQA plates. This dramatically expands implement options—pallet forks, grapples, augers, trenchers, and specialized buckets designed for skid steers become compatible with your tractor.

Proprietary systems:

John Deere, Kubota, and some other manufacturers use proprietary loader quick-attach systems. These require brand-specific implements or adapter plates to use SSQA implements.

Drawbar-Mount Quick-Hitch

Some implements attach to the drawbar (the horizontal bar at the rear of the tractor below the three-point hitch). Trailers, certain spreaders, and pull-type equipment use drawbar attachment.

Standard drawbar sizes:

- Category 1: 1-1/4 inch diameter pin, 1-3/4 inch clevis

- Category 2: 1-3/4 inch diameter pin, 2-1/4 inch clevis

Quick-release drawbar pins with handle locks simplify attachment compared to traditional clevis pins with cotter pins.

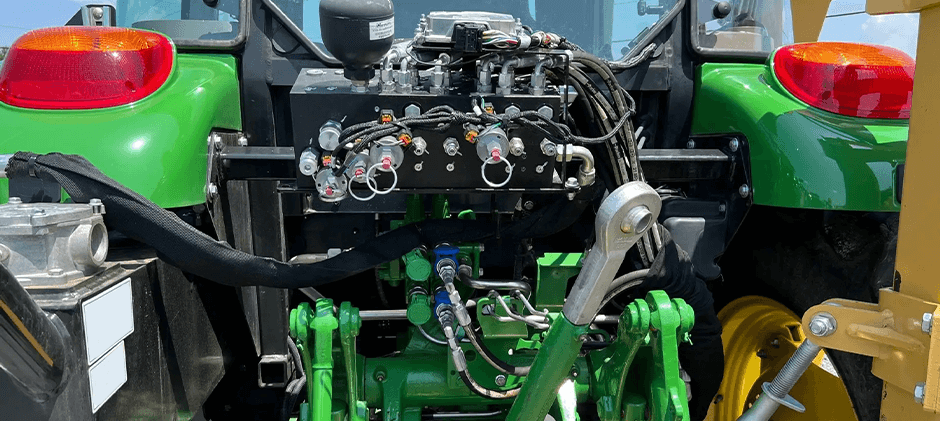

Rear Remote Hydraulic System Compatibility

Implements requiring hydraulic power—top and tilt for blades, rotation for augers, opening/closing for grapples—need connection to the tractor’s hydraulic system via rear remote valves.

Knowing Rear Remote Valves

Rear remote hydraulic valves are externally-mounted control valves that direct hydraulic fluid to implement cylinders and motors. They’re typically located on the rear fenders or beneath the seat within easy reach of the operator.

Single-acting valves: Control one hydraulic function with fluid flow in one direction. The implement returns to neutral position via gravity or a spring. Used for: top link cylinders, simple dump functions.

Double-acting valves: Control hydraulic functions requiring powered movement in both directions. Used for: grapple open/close, blade angle, auger rotation, log splitter extension/retraction.

Number of remotes: Tractors come with 0, 1, 2, or 3 rear remote valves depending on model and configuration. You can typically add remotes up to the system’s capacity.

Hydraulic Coupler Types

The physical connection between your tractor’s remote outlets and the implement’s hydraulic hoses uses quick-disconnect couplers. Multiple coupler standards exist causing compatibility headaches.

Pioneer/Ag (Flat Face) Couplers:

The most common type for agricultural equipment. These have flat faces that mate together and lock with a collar or sleeve.

- 1/4 inch Pioneer: Common on compact tractors, 5-10 GPM capacity

- 3/8 inch Pioneer: Common on larger utility tractors, 10-20 GPM capacity

- 1/2 inch Pioneer: Heavy agricultural applications, 20-30 GPM capacity

Pioneer couplers are not interchangeable between sizes. A 1/4-inch male won’t fit a 3/8-inch female.

ISO 7241-1 Series A (Poppet Type):

International standard used on many implements and newer tractors. Similar to Pioneer but with slightly different dimensions.

- ISO A 1/4 inch: 5-10 GPM capacity

- ISO A 3/8 inch: 10-20 GPM capacity

ISO and Pioneer couplers of the same nominal size are not directly interchangeable despite similar appearance. Forcing them together damages seals and causes leaks.

ISO 16028 (Flat Face, High Pressure):

Newer standard for higher pressure and flow applications. Common on construction equipment and high-performance implements.

These are generally not compatible with agricultural Pioneer or ISO A couplers without adapters.

Faster/Hansen Series:

Proprietary quick-disconnect couplers used on some European equipment.

Again, not compatible with Pioneer or ISO A couplers without adapters.

Quick-Disconnects vs. Thread-Together:

Some implements use threaded hydraulic connections (JIC, NPT, BSPP) instead of quick-disconnects. These require wrenches to connect/disconnect and take significantly longer to swap between implements.

Checking Your Tractor’s Coupler Type

Most tractors use Pioneer-style couplers, but verify your specific type:

- Measure the coupler diameter (1/4″, 3/8″, or 1/2″)

- Check your operator’s manual for specification

- Look for markings on the coupler body

- Bring the tractor to a hydraulic supply store for identification

Matching Implements to Tractor Hydraulics

For proper operation, the implement’s hydraulic requirements must match your tractor’s hydraulic system capacity.

Flow rate (GPM – Gallons Per Minute):

This is how much hydraulic fluid the tractor’s pump delivers per minute. Compact tractors typically provide 5-8 GPM; utility tractors 8-15 GPM; agricultural tractors 15-30+ GPM.

Implements specify minimum and maximum flow rates. A high-flow hydraulic auger requiring 12-15 GPM won’t operate properly on a compact tractor supplying only 6 GPM—it rotates slowly or stalls under load.

Conversely, a small implement designed for 5 GPM operates fine on a tractor supplying 15 GPM as long as the pressure is correct and the implement has flow control.

Operating pressure (PSI):

Most tractor hydraulic systems operate at 2,000-2,500 PSI for three-point hitch and rear remotes. Implements are designed for this range.

Some specialized implements require higher pressure (3,000+ PSI). Verify your tractor’s relief valve setting matches the implement’s requirements.

Oil type:

Tractor hydraulic systems use multi-purpose tractor hydraulic fluid (UTF), which is compatible with implement hydraulic cylinders and motors. Don’t mix AW hydraulic oil, ATF, or motor oil in systems using UTF.

Hydraulic hose length:

Implements come with hydraulic hoses of varying length (typically 6-12 feet). Ensure hoses are long enough to reach from your tractor’s remote outlets to the implement’s cylinders without excessive stretching, but not so long they drag the ground.

Too-short hoses pull apart during articulation. Too-long hoses get caught in moving parts or run over.

Adapter Fittings and Conversion

When your tractor’s couplers don’t match your implement’s fittings, adapter sets provide compatibility.

Pioneer 1/4″ to 3/8″ adapters:

Allow 1/4-inch tractor outlets to connect to 3/8-inch implement hoses. Note this doesn’t increase flow—the restricting factor remains the smaller coupler.

Pioneer to ISO A adapters:

Convert between Pioneer and ISO A standards within the same size class.

Thread adapters:

Convert from quick-disconnect to threaded connections or between different thread standards (JIC to NPT, etc.).

Flow control valves:

Inline flow control valves restrict hydraulic fluid flow protecting implements designed for low flow when connected to high-flow tractors.

Adapters are available from hydraulic supply stores, tractor dealers, and online retailers. Quality adapters use proper seals and materials preventing leaks. Cheap adapters fail quickly and leak.

Electrical Compatibility

Some implements require electrical power for lights, clutches, or controls.

Tractor electrical outlet types:

7-pin round trailer plug:

Standard for trailers and some implements requiring lights. Provides running lights, turn signals, brake lights, and ground.

Cigar lighter/power port:

12-volt DC accessory power for cab accessories, GPS, or implement controls.

ISO 11783 (ISOBUS):

Standardized electronic communication system allowing implements and tractor computers to communicate. High-end tractors and precision agriculture equipment use ISOBUS for sophisticated control.

Proprietary electrical systems:

Some implements use manufacturer-specific electrical connections requiring adapters.

Most basic implements don’t require electrical connection beyond safety lights for road transport.

Common Quick-Hitch and Rear Remote Compatibility Issues and Solutions

Issue: Implement quick-hitch pins don’t line up with your quick-hitch frame

Solution: Check that implement is rated for your category (Cat 1, Cat 2, etc.). If correct category but wrong brand geometry, drill new holes in implement mounting plate to match your quick-hitch, or fabricate adapter plates.

Issue: Hydraulic couplers don’t connect

Solution: Identify your tractor’s coupler type (Pioneer 1/4″, 3/8″, ISO A, etc.) and implement’s fitting type. Purchase appropriate adapters. Ensure male/female orientation matches.

Issue: Hydraulic implement operates sluggishly or not at all

Solution: Check that tractor’s GPM output meets implement’s minimum requirement. Verify remote valve is configured for double-acting if implement requires it. Check for kinked or damaged hoses. Verify fluid level in tractor reservoir.

Issue: Three-point hitch won’t lift implement

Solution: Check that implement weight doesn’t exceed tractor’s lift capacity at the mounting distance. Ensure lower link ends aren’t bottoming out. Verify implement is category-appropriate for your tractor.

Issue: Quick-hitch engages only 2 of 3 points

Solution: Adjust implement or quick-hitch geometry. Some implements need shimming or link length adjustment to align all three mounting points with the quick-hitch frame.

Issue: Implement sits too low or too high

Solution: Adjust top link length. Ensure lower links are properly positioned. Some implements need spacers or different hole positions to achieve proper working height.

Buying Implements: Quick-Hitch and Rear Remote Compatibility Checklist

Before purchasing a new or used implement, verify:

Three-point hitch compatibility:

- Implement category matches tractor category (Cat 0, 1, 2, or 3)

- Implement weight within tractor’s lift capacity

- Implement has quick-hitch mounting or can be adapted

Hydraulic compatibility (if hydraulically powered):

- Tractor has sufficient rear remote valves (single or double-acting as required)

- Tractor’s GPM meets or exceeds implement’s minimum requirement

- Tractor’s hydraulic pressure matches implement specification

- Coupler types match or adapters are available

- Hose length is appropriate

Physical compatibility:

- Tractor has sufficient clearance for implement during operation and turning

- Implement width is appropriate for tractor size and tire spacing

- Ground clearance is adequate

PTO compatibility (if PTO-powered):

- Tractor PTO speed matches implement requirement (540 RPM or 1000 RPM)

- PTO shaft type compatible (6-spline, 21-spline, etc.)

- Implement driveline length matches tractor PTO to implement input spacing

Electrical compatibility:

- Tractor has required electrical outlets if implement needs power

- Wiring adapters available if needed

Recommended Implement Combinations by Tractor Size

Sub-compact tractors (under 25 HP, Cat 0):

- Finish mowers: 48-60 inches

- Box blades: 4-5 feet

- Rear blades: 4-5 feet

- Tillers: 36-48 inches

- Post hole diggers: Single auger, 6-9 inch diameter

- Spreaders: Small broadcast or drop spreaders

Compact tractors (20-40 HP, Cat 1):

- Rotary cutters: 4-5 feet

- Finish mowers: 60-72 inches

- Box blades: 5-6 feet

- Rear blades: 5-6 feet

- Tillers: 48-60 inches

- Post hole diggers: Single auger, 9-12 inch diameter

- Disc harrows: 4-5 feet

- Backhoes: Light-duty, 6-8 foot dig depth

Utility tractors (40-75 HP, Cat 1 or Cat 2):

- Rotary cutters: 5-7 feet

- Finish mowers: 6-8 feet

- Box blades: 6-7 feet

- Rear blades: 6-7 feet

- Tillers: 60-72 inches

- Post hole diggers: Dual auger possible, 12-18 inch diameter

- Disc harrows: 6-8 feet

- Backhoes: Standard duty, 8-12 foot dig depth

- Balers: Small square balers

Aftermarket Parts and Universal Implements

Quality aftermarket implements and attachment parts offer cost savings compared to original equipment manufacturer (OEM) parts without sacrificing functionality.

FridayParts offers hydraulic couplers, adapter fittings, quick-hitch components, and three-point hitch hardware compatible with major tractor brands at competitive prices. From Pioneer couplers to ISO adapters, we stock the connections you need to make your implements work with your tractor.

FAQs About Tractor Quick-Hitch and Rear Remote Compatibility

Can I use a Cat 2 implement on a Cat 1 tractor?

Not safely. The Cat 2 pins are larger (1-1/8″ vs 7/8″) and won’t fit Cat 1 lower links without dangerous modification. Additionally, Cat 2 implements are typically heavier than Cat 1 tractors can safely lift. Always match implement category to tractor category.

Will any quick-hitch work with any implement?

No. Quick-hitches must match the tractor’s category, and the implement must have mounting compatible with that specific quick-hitch’s geometry. While most follow general standards, exact hole spacing varies between brands. Universal-mount implements with multiple hole positions offer best compatibility.

Can I add rear remotes to a tractor that doesn’t have them?

Usually yes, but it requires professional installation. The tractor’s hydraulic system must have sufficient pump capacity, and the valve assembly must tap into the system correctly. Dealers can add factory remote kits; hydraulic shops can install aftermarket systems. Expect $500-1,500 depending on complexity.

What’s the difference between single-acting and double-acting hydraulic valves?

Single-acting valves provide hydraulic pressure in one direction only—the cylinder or function returns via gravity or spring. Double-acting valves provide powered movement in both directions. Most implements requiring precise control (grapples, tilting blades, log splitters) need double-acting remotes.

Can I use Pioneer couplers with ISO implements?

Not directly—they’re different standards despite similar appearance. You need adapter fittings to convert between Pioneer and ISO couplers. Verify the size (1/4″, 3/8″, 1/2″) and standard (Pioneer vs ISO A vs ISO B) and purchase the appropriate adapters.

How do I know if my implement needs more hydraulic flow than my tractor provides?

Check your tractor’s specifications for GPM output (typically in the operator’s manual or spec sheet). Compare to the implement’s minimum GPM requirement (on implement specs or manual). If the tractor provides less than the implement needs, the implement will operate slowly or not at all. Flow control valves can reduce excess flow but cannot increase insufficient flow.

Knowing quick-hitch and rear remote compatibility prevents frustration, unsafe conditions, and expensive mistakes. Match implements to your tractor’s category, hydraulic capacity, and coupler type for reliable operation. When you need adapters, fittings, or compatibility components, FridayParts stocks quality solutions at fair prices, helping you connect implements properly and work productively.