The Milwaukee Tools are famous for their durability and high price, so individuals may wonder where Milwaukee tools are made and whether they deserve their reputation. This guide will introduce the global Milwaukee manufacturer locations and their features, and help you decide whether you should buy one.

Where to Source the Milwaukee Tools?

Milwaukee Tool was founded in 1924 and has never lost its American DNA. The company’s global headquarters and primary R&D center remain in Brookfield, Wisconsin, near Milwaukee. Alongside offices in Menomonee Falls, Mukwonago, Sun Prairie, and other Wisconsin locations, this region continues to serve as the creative hub for product design, engineering, and advanced manufacturing technologies.

According to the Wisconsin Economic Development Corporation, Milwaukee Tool employs over 10,000 American workers and actively invests in local communities, building long-term partnerships with suppliers, construction firms, and schools. The company’s deep Wisconsin roots reinforce trust in its innovation-first culture and “Badger State” values of fairness and community service.

Global Manufacturing Footprint

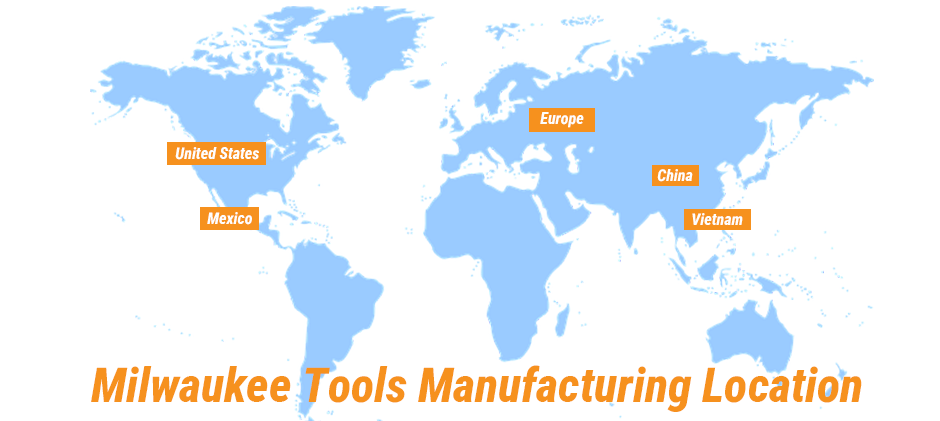

While its design heartbeat is in the U.S., Milwaukee Tool operates as a modern global manufacturer. Production is strategically distributed to optimize efficiency and meet demand worldwide:

United States (Wisconsin, Mississippi, Indiana, Tennessee)

- Precision Sawzall blades

- Bi-metal and carbide hole saws

- Step drill bits

- Select hand tools

- Specialty assembly facilities with temperature-controlled heat treatment lines

Highlights

Although much of Milwaukee’s line is produced overseas, the company preserves an important U.S. manufacturing base. Products proudly marked with the “Made in USA with Global Materials” emblem include:

- SAWZALL® reciprocating saw blades

- HOLE DOZER™ bi-metal and carbide tooth hole saws

- Step drill bits

- Select hand tools

Each of these tools undergoes rigorous processes, such as precision heat treatment in Milwaukee’s Wisconsin facilities, which results in harder, sharper, and longer-lasting cutting edges. This emphasis demonstrates an ongoing commitment to sustain and even expand American manufacturing capabilities.

Mexico

- High-volume assembly for cordless power tools

- Packaging and distribution for North American markets

China

- Major production site for M18 and M12 cordless platforms

- Wide range of lithium-ion power tools and combo kits

- Complex electronics assembly and OEM supply chain management

Vietnam

- Rapidly expanding factory base supporting cordless drill production and accessories

- Supports Milwaukee’s growth in Southeast Asia

Europe

- Premium hand tools and specialty items for EU demand

- Distribution hubs improving logistics for European customers

This global network of factories enables Milwaukee to scale production, control costs, and remain competitive in a rapidly changing power tool market.

Same Standard of Milwaukee Tools Worldwide

The most critical takeaway: every Milwaukee tool must meet the same global quality standards, regardless of where it is from. Whether produced in Tennessee or Vietnam, all plants use

Milwaukee’s strict specifications for durability, safety, and performance.

This ensures that:

Professionals receive consistent, pro-grade quality worldwide

The same ISO-certified processes are followed across factories

Global sourcing and testing guarantee long-term reliability

Reliable Aftermarket Milwaukee Tools From FridayParts

At FridayParts, we apply a parallel philosophy to tool maintenance and repair. We understand that a high-performance tool is only as strong as its weakest component. Just as Milwaukee promises the performance of their tools, we also ensure that our aftermarket Milwaukee tool parts meet OEM quality standards and undergo rigorous testing.

Find aftermarket Milwaukee power tool parts at FridayParts, enjoy fast delivery & global shipping to restore your reliable tools at a competitive cost!