To keep your machinery in its optimal performance, trapped air is a tricky problem. To maintain your productivity and operational safety, the solution is to “bleed” the system. But how to bleed a hydraulic cylinder? This guide will tell you two methods for solving this problem. One is easy with a bleeder valve; the other is more challenging without one. This guide will walk you through both procedures step-by-step, explain why it’s so critical, and explain why one method is better.

Why Bleeding is Non-Negotiable

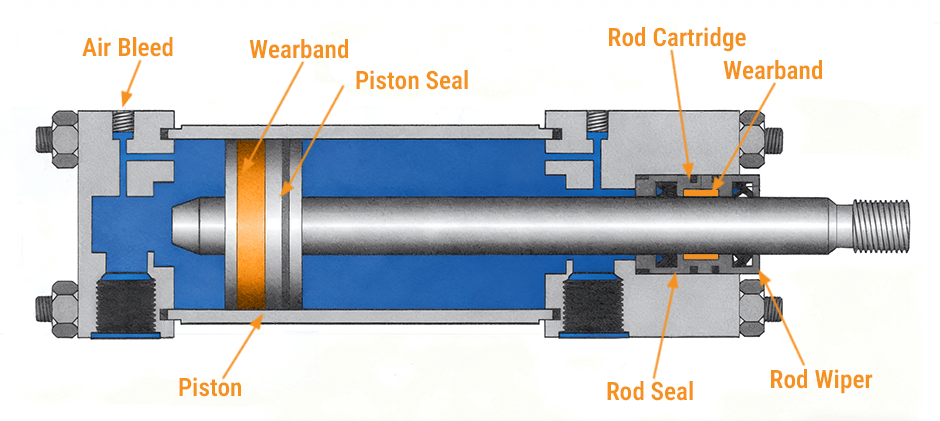

Hydraulic systems are designed to work with incompressible fluid, not air. When air gets into the system (known as entrained air), it dramatically changes how the cylinder performs. This is why bleeding is so important:

- Performance Issues: Trapped air compresses, leading to pressure drops, sluggish or jerky responses (“spongy” operation), and loud knocking or banging noises as the air rapidly compresses and decompresses. These are major warning signs for your hydraulic system.

- Cavitation Damage: This is the most severe consequence. When the pressure changes rapidly, tiny vapor-filled cavities can form in the hydraulic fluid. As these cavities move into high-pressure zones within the cylinder, they implode violently. This implosion erodes metal components like seals and cylinder walls, contaminating the fluid with particles and leading to a chain reaction of damage that ultimately causes component failure.

When Should You Bleed a Hydraulic Cylinder?

You should always bleed your hydraulic cylinders at two key times:

- Upon First Installation: A new cylinder or hose will always contain air that must be purged before the equipment is put into service.

- After Any Repair or Maintenance: Any time the hydraulic system is opened (e.g., to find the right seal kit for a hydraulic cylinder, replace a hose, or component), air will enter and must be removed. This is an essential step if you rebuild a hydraulic cylinder.

You should also do bleeding to the system if your eye sees out the kind of air being trapped, like having a knocking sound come out, or the cylinder making a soft-soft, not steady reply.

How to Bleed a Hydraulic Cylinder With a Bleeder Valve

1. Preparations

Gather Supplies: Collect a small wrench for the valve, safety glasses, and a clean, clear container partially filled with new hydraulic fluid.

- Set Up for Cleanliness & Visibility: Attach a clear tube to the bleed valve’s nipple and place the other end into the container. This prevents spills and allows you to see escaping air bubbles.

- Secure the Machine: Ensure the equipment is safely parked and secured against any movement.

2. Position the Cylinder to Trap Air

Air always rises, so operate the cylinder to move the trapped air to the highest point, which is near the bleed valve. The procedure can vary slightly depending on whether it’s a single vs double acting hydraulic cylinder.

Execute the Action:

- To bleed the rod-end, fully extend the piston.

- To bleed the cap-end, fully retract the piston.

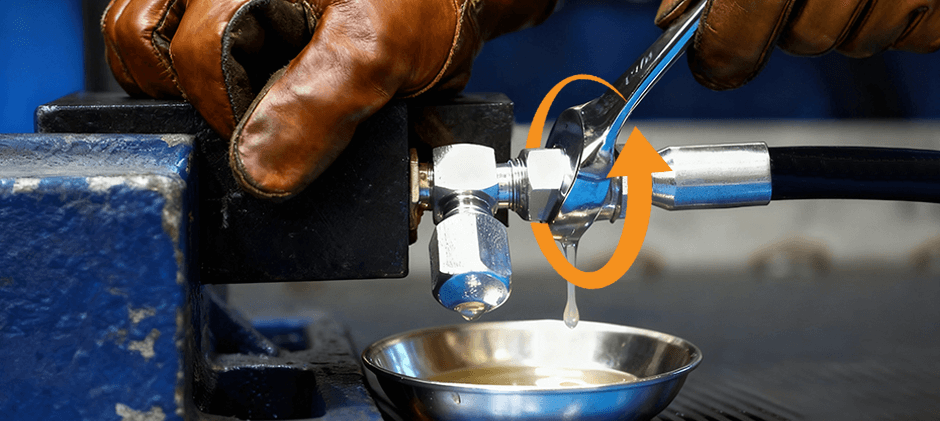

3. Carefully Open the Bleed Valve

- Apply Light Pressure: Hold the cylinder under slight hydraulic pressure.

- Action: Use your wrench to slowly turn the bleed valve counter-clockwise (a half-turn is often enough).

- Listen: You should immediately hear a hissing sound as the trapped air begins to escape.

4. Observe the Fluid and Purge the Air

- Monitor the Output: Keep the valve open and watch the fluid exiting the tube. Initially, it will likely be foamy or have visible air gaps.

- Determine Completion: Continue the process until the hissing stops and the fluid stream becomes solid, clear, and completely free of bubbles.

5. Close the Valve and Test the System

- Seal the System: As soon as the fluid stream is clear, promptly tighten the bleed valve.

- Clean Up: Wipe away any residual fluid from the valve and cylinder.

- Verify the Result: Cycle the cylinder through its full range of motion several times to confirm it operates smoothly.

- Troubleshoot: If any jerkiness or spongy feeling persists, repeat the entire process, as a small amount of air may still be trapped.

How to Bleed a Hydraulic Cylinder Without a Bleeder Valve

This method is more complex and requires extreme care. It involves using the system’s own components and fittings to purge the air.

WARNING: High-Pressure Injection Hazard

This method can be dangerous. Hydraulic fluid under pressure can penetrate the skin, causing severe injury, gangrene, or even amputation. Always wear safety glasses and thick gloves. Never use your hands to check for leaks. Proceed with extreme caution.

There are two common techniques for this method:

Technique A: Cracking the Fitting

- Identify the Highest Bleed Point: Position the cylinder to trap air at one end. Identify the highest hydraulic line fitting on that end of the cylinder. This is your bleed point. Place a large drip pan and absorbent rags underneath.

- Apply Gentle Pressure: Have an assistant operate the controls to apply slow, steady pressure to the line you are bleeding.

- EXTREMELY SLOWLY Crack the Fitting: Using the correct size wrench, incrementally and very slowly loosen the fitting (approx. 1/8 to 1/4 of a turn). You will hear a hiss as air escapes.

- Tighten Immediately: The moment you see solid fluid weeping from the threads, immediately tighten the fitting back to its proper torque.

- Cycle and Repeat: Cycle the cylinder 5-10 times to move remaining air to the ports, then repeat the process until the operation is smooth.

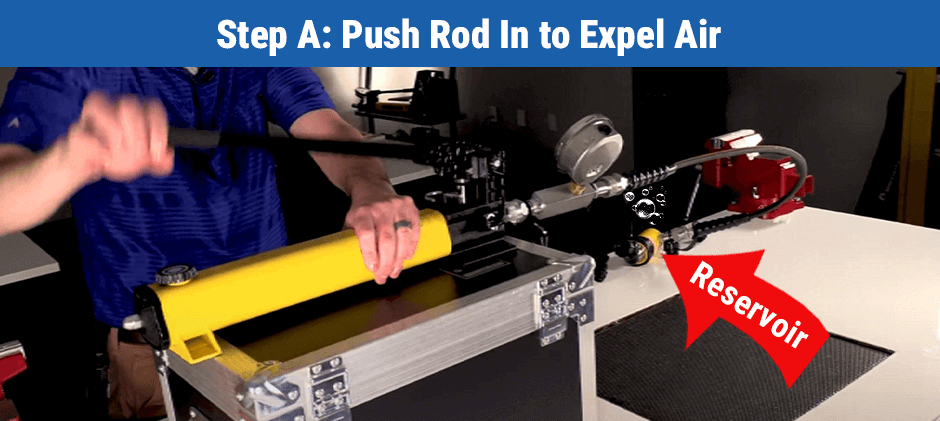

Technique B: Back-Bleeding(For Smaller Cylinders)

- Disconnect and Position: If possible, disconnect the cylinder from its mounting point but leave the hydraulic line attached. Hold the cylinder at an angle so that the line of connection is the absolute highest point.

- Manually Compress: Have an assistant watch the master cylinder fluid reservoir. Manually and slowly push the cylinder’s pushrod all the way in. This will force the fluid and trapped air back up the line and into the reservoir. You should see bubbles appear in the reservoir. (Note: This is only feasible for smaller cylinders that can be moved by hand.)

- Slowly Release and Repeat: Allow the pushrod to return slowly, drawing fresh fluid from the reservoir. Repeat this process until no more air bubbles can be seen rising in the reservoir fluid.

- Re-install and Test: Once no more bubbles are present, the air is purged. Reinstall the cylinder and test for proper operation.

Key Differences at a Glance

| Feature | With a Bleed Valve | Without a Bleed Valve |

|---|---|---|

| Difficulty | Simple & Direct | Complex & Technical |

| Safety | High. The process is fully controlled. | Low / Risky. Risk of high-pressure fluid injection. |

| Efficiency | Fast. Air is purged in one or two cycles. | Slow & Repetitive. Requires multiple cycles. |

| Cleanliness | Clean. Fluid can be routed to a container. | Messy. Spills and drips are almost unavoidable. |

Choose the Right Way and the Right Parts

The verdict is clear: as the comparison table illustrates, using a bleed valve is the professional choice for bleeding a hydraulic cylinder. It’s faster, safer, and cleaner, making the alternative method only for emergencies. This highlights the importance of investing in well-designed, serviceable components.

At FridayParts, we champion this principle by offering not just a wide selection of Hydraulic & Pneumatic Valves, but all the hydraulic cylinder components you need to ensure your machinery is easy to maintain and runs perfectly. Visit FridayParts.com today and equip yourself for a job done right.