Single vs double acting hydraulic cylinder sounds familiar, but did you ever wonder what the difference is? This guide will introduce them from the definition, advantages, and disadvantages to applications and their key differences. Besides, you can also learn how to bleed them specifically. Knowing these can not only help you maintain their performance, but also select the right Hydraulic Cylinder Components more effectively. Follow and learn now.

What is a Single Acting Hydraulic Cylinder?

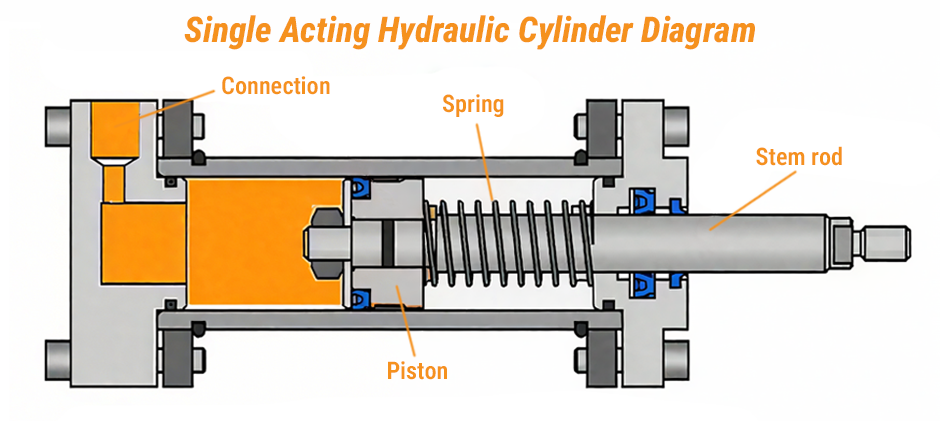

A single acting hydraulic cylinder is a linear actuator where hydraulic fluid pressure is applied to only one side of the piston to generate movement in a single direction. The return stroke is not powered by hydraulics; instead, it relies on an external force like an internal spring, gravity, or the weight of the load itself. This simple design requires only one hydraulic port for fluid to enter and exit.

Pros

- Simple design and fewer components

- Lower initial cost for the cylinder and control system

- Easier and less expensive maintenance

- Predictable resting state in case of pressure loss

Cons

- Provides powered motion in one direction only

- Uncontrolled and often slower return stroke

- Spring-return models can be bulky

- Inconsistent return stroke as springs wear over time

Application

A single acting hydraulic cylinder is perfect for jobs requiring a powerful force in one direction, where the return stroke is not critical.

- Lifting: Hydraulic presses, car jacks, and pallet jacks.

- Clamping: Holding workpieces in position for manufacturing processes.

- Punching or Marking: Stamping applications on a factory assembly line.

Single Acting Hydraulic Cylinder Diagram

What is a Double Acting Hydraulic Cylinder?

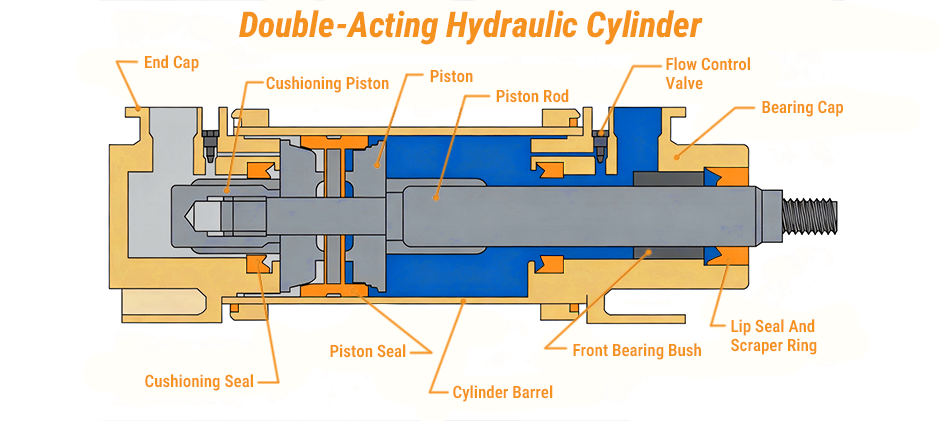

A double acting hydraulic cylinder uses hydraulic pressure to power movement in both directions—extension and retraction. It features two hydraulic ports, one on each end. By directing pressurized fluid to the appropriate port, an operator can exert precise, powered control over the piston’s movement back and forth, making it faster, stronger, and more versatile.

Pros

- Provides precise, powered control over both extension and retraction

- Faster, stronger, and more consistent cycle times

- Highly versatile and can be operated in any orientation

- Often more energy-efficient for complex tasks

Cons

- Higher initial cost for the cylinder, valves, and extra hoses

- More complex design with more seals and potential failure points, which may require you to find the right seal kit for a hydraulic cylinder during maintenance.

- Requires more involved maintenance and repair

Application

A double acting hydraulic cylinder is essential for any task that demands powered, controlled motion in two directions.

- Earthmoving Equipment: Operating excavator arms, bulldozer blades, and steering systems.

- Material Handling: Powering forklifts, elevators, and industrial lifts.

- Industrial Automation: Driving robotic arms, complex presses, and any machine requiring precise back-and-forth motion.

Double Acting Hydraulic Cylinder Diagram

How to Bleed Your Single vs Double Acting Hydraulic Cylinder

Trapped air is the enemy of a hydraulic system. It causes spongy, jerky operation (“juddering”), reduces efficiency, and can lead to catastrophic damage through cavitation. Bleeding, or purging, the air from the system is a non-negotiable maintenance task after any repair or upon first installation. For a more detailed walkthrough, see our complete guide on how to bleed a hydraulic cylinder.

SAFETY FIRST: Hydraulic fluid under pressure can be injected into the skin, causing severe injury or death. Always wear safety glasses and thick, fluid-resistant gloves. Never use your hands to check for leaks. Proceed with extreme caution.

How to Bleed a Single Acting Hydraulic Cylinder

Bleeding a single acting cylinder is challenging because you only have one port. The method varies based on its return mechanism.

For Gravity or Load-Return Cylinders:

- Position Cylinder: If possible, orient the cylinder so its single port is at the highest point, encouraging air to gather there.

- Apply Gentle Pressure: Extend the cylinder partway to fill it with fluid.

- Slowly Loosen Fitting: Using the correct wrench, EXTREMELY SLOWLY crack open the hydraulic fitting at the cylinder’s port (a 1/8 turn is often enough). You should hear a hissing sound as air begins to escape.

- Allow Cylinder to Retract: Let gravity or the load slowly push the cylinder back to its retracted position. This action forces the trapped air, followed by fluid, out through the loosened threads.

- Observe and Tighten: When you see a solid, bubble-free stream of fluid weeping from the fitting, immediately tighten it to the right torque.

- Cycle and Repeat: Wipe the area clean. Cycle the cylinder a few times to confirm smooth operation. If jerkiness persists, repeat the process.

For Spring-Return Cylinders:

- Extend Cylinder: Operate the controls to fully extend the cylinder, compressing the internal spring.

- Slowly Loosen Fitting: Carefully and slowly crack open the fitting at the cylinder’s port.

- Activate Return: Operate the control valve to allow retraction. The force of the compressed spring will push the piston, forcing air and fluid out of the loosened fitting.

- Observe and Tighten: As soon as the fluid stream is solid and free of bubbles, promptly tighten the fitting.

- Cycle and Repeat: Clean any spilled fluid and cycle the system several times to ensure all air has been purged.

How to Bleed a Double Acting Hydraulic Cylinder

Bleeding a double acting cylinder is much easier because you can use hydraulic pressure to purge air from both sides.

Method 1: Using Bleeder Valves

- Prepare: Attach a clear tube to the bleeder valve on one end of the cylinder. Place the other end of the tube into a clean container partially filled with hydraulic fluid.

- Bleed the Rod End: Fully retract the piston rod. This moves air to the rod-end port. With the machine at low idle, slightly open the rod-end bleeder valve. You will hear hissing and see bubbles in the tube. Keep it open until the fluid stream is solid, then close the valve.

- Bleed the Cap (Barrel) End: Fully extend the piston rod. This moves air to the cap-end port. Move your tube to the cap-end bleeder valve. Slightly open the valve until the fluid stream is solid, then close it.

- Test: Cycle the cylinder back and forth 5-10 times to confirm smooth operation and work out any remaining air pockets. Repeat if necessary.

Method 2: Cracking the Fittings

- Bleed One Side: Fully extend the cylinder. SLOWLY loosen the hydraulic fitting on the cap-end port. Have an assistant slowly operate the control to begin retracting the cylinder. The moment the solid fluid weeps out, tighten the fitting.

- Bleed the Other Side: Fully retract the cylinder. SLOWLY loosen the hydraulic fitting on the rod-end port. Have the assistant slowly operate the control to begin extending the cylinder. The moment the solid fluid weeps out, tighten the fitting.

- Cycle and Repeat: Cycle the cylinder 5-10 times to move any remaining air toward the ports. Repeat the bleeding process if the operation is still not perfectly smooth.

Single Vs Double Acting Hydraulic Cylinder: Key Differences

While both convert fluid power to work, their operational methods, capabilities, and ideal use cases are fundamentally different. Choosing the wrong type can lead to poor performance, higher costs, and operational inefficiencies.

A single acting cylinder is a specialist: simple, inexpensive, and perfect for one-way force applications. A double acting cylinder is a versatile powerhouse, offering complete control at a higher complexity and cost.

| Feature | Single Acting Cylinder | Double Acting Cylinder |

|---|---|---|

| Principle | Hydraulic force in one direction only. | Hydraulic force in both directions. |

| Control | Low control; passive, uncontrolled return. | High control; precise, powered motion both ways. |

| Construction | Simple, one port, may have a spring. | Complex, two ports, more internal seals. |

| Return Stroke | By spring, gravity, or external load. | Powered by hydraulic pressure. |

| System Cost | Lower (cylinder, valve, hoses). | Higher (cylinder, valve, hoses). |

| Speed & Cycles | Slower due to passive return. | Faster, more consistent cycle times. |

Which One Should You Choose

Finally, the choice of a single and double-acting cylinder depends on performance, control, and cost.

Choose a single-acting cylinder when:

- Force is needed in only one direction.

- The return stroke can rely on gravity or a spring.

- Simplicity and lower cost are your top priorities.

Choose a double-acting cylinder when:

- Powered, controlled motion is required in both directions.

- Speed, precision, and consistent cycles are essential.

- High performance is needed regardless of orientation.

Whatever hydraulic cylinder you choose, FridayParts is always your good partner. We offer a wide range of high-quality hydraulic cylinder components, from cost-effective single-acting hydraulic cylinders to robust double-acting hydraulic cylinders. If you need a replacement, make sure you know how to measure a hydraulic cylinder to get the perfect fit.

Visit today to enjoy our responsive service and fast delivery & global shipping!